Metal Halide Expose Machine

Price 275000.00 INR/ Unit

Metal Halide Expose Machine Specification

- Type

- Metal Halide Expose

- Computerized

- Yes

- Automatic Grade

- Semi-Automatic

- Plate Type

- Other

- Print Direction

- Other

- Ink Type

- Other

- Color Management

- Other

- Power

- 440 Volt (v)

- Warranty

- One Year

Metal Halide Expose Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Western Union, Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1-2 Week

- Packaging Details

- wooden packing

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, Uttarakhand, Daman and Diu, All India, Lakshadweep, Chhattisgarh, Assam, Delhi, Meghalaya, Maharashtra, Karnataka, Telangana, Kerala, Jammu and Kashmir, Sikkim, Goa, East India, Jharkhand, Mizoram, Andhra Pradesh, Tripura, South India, Bihar, Pondicherry, Arunachal Pradesh, Rajasthan, Manipur, Tamil Nadu, Haryana, Gujarat, West Bengal, Madhya Pradesh, North India, Punjab, Uttar Pradesh, Central India, Odisha, West India

About Metal Halide Expose Machine

Metal Halide Expose Machine 32" X 42"

Angular type exposing machine of Umrao Automation Pvt.Ltd. is built from square tube pipe frames. This exposing systems offers remarkable combination of performance control and safety features. Engineered to keep the glass surface cool and uniformity in exposure from center to corner of the frame. Top Blanket frame movement via gas cylinder assists in easy, smooth & safe operation which is maintenance free. Automatic operations, you just load the frame, press start aand walk away system.

STANDARD FEATURES

- Oil less vacuum pump 0.5 HP

- Reliable damper system (DC motor 1/6 HP operator)

- Special electronic circuit makes machine user friendly

- Digital pulse counter

- Imported vacuum (Rubber) blanket for better contact between stencil & film

- Automatic standby mode facility for power saving. Shutter release system helps screen to expose one after another without switching off the lamp

- Metal halide lamp

- Air blower for lamp cooling

- Cooling system to keep glass surface cool

- Hour meter for lamp

- 10 mm optically clear glass

- Safety switch

TECHNICAL SPECIFICATION

| Model No. | Maximum Frame Size | Machine Size | Weight (Approx) | Metal halide lamp (Watts) |

| Auto Expose 1212 | 12" X 12" | 26"(W)X32"(L)X40" (H) | 100kg | 1.0 Kw 440 V AC |

| Auto Expose 2025 | 20" X 25" | 32"(W)X39"(L)X43" (H) | 120kg | 1.5 Kw 230 V AC |

| Auto Expose 3848 | 38" X 48" | 52"(W)X60"(L)X43"(H) | 135kg | 2.0 Kw 440 V AC |

| Auto Expose 4040 | 40" X 40" | 48"(W)X48"(L)X43"(H) | 135kg | 2.0 Kw 440 V AC |

| Auto Expose 4858 | 48" X 58" | 62"(W)X70"(L)X43"(H) | 150kg | 3.0 Kw 440 V AC |

| Auto Expose 5468 | 54" X 68" | 74"(W)X88" (L)X43(H) | 165kg | 5.0 Kw 440 V AC |

Efficient Exposure Technology

This Metal Halide Expose Machine leverages state-of-the-art computerized systems, delivering consistent and uniform light exposure for critical applications. It ensures reproducible quality for screen printing and PCB manufacturing, enabling users to maintain top-notch standards in their productions.

User-Friendly Operation

Designed with a semi-automatic interface, the machine is easy to operate and requires minimal manual intervention. Its computerized control system simplifies workflow, making it suitable for both seasoned professionals and newcomers seeking accuracy and reliability.

FAQs of Metal Halide Expose Machine:

Q: How does the Metal Halide Expose Machine operate?

A: The machine uses a metal halide light source to expose screens or photosensitive materials, controlled by a computerized system to automate timing and light intensity. Operators simply set the required parameters, and the semi-automatic process handles the rest.Q: What types of industries commonly use this exposure machine?

A: Industries such as screen printing, PCB manufacturing, and related sectors utilize this machine for its accuracy and efficiency in exposing screens and photoresist materials.Q: When should I perform routine maintenance on the machine?

A: It is recommended to conduct routine maintenance every few months or after extensive use, including cleaning the light source area and checking electronic components, to ensure optimal performance and longevity.Q: Where is this Metal Halide Expose Machine manufactured and supplied from?

A: This machine is manufactured and supplied by an established exporter in India, offering reliable distribution both domestically and internationally.Q: What is the typical process for exposing materials with this machine?

A: Operators place the material on the machines bed, set desired exposure time and intensity through the computerized panel, and initiate the semi-automatic cycle. The machine then exposes the material evenly as programmed.Q: How does using a semi-automatic, computerized machine benefit users?

A: Users benefit from greater consistency in exposure quality, reduced manual effort, and minimized errors. The computerized, semi-automatic system also enhances productivity and ensures reliable outputs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre Press Machine Category

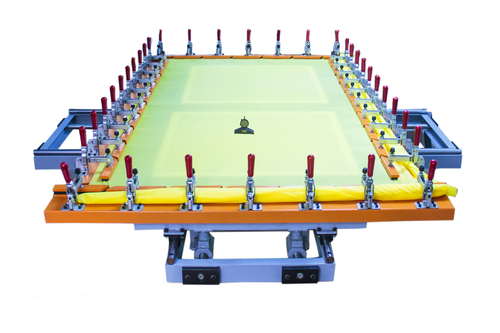

Screen Stretching Machine

Price 410000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Size : 66 W x 90 L x 35 H

Computerized : Yes

Type : Stretching Machine

Warranty : One Year

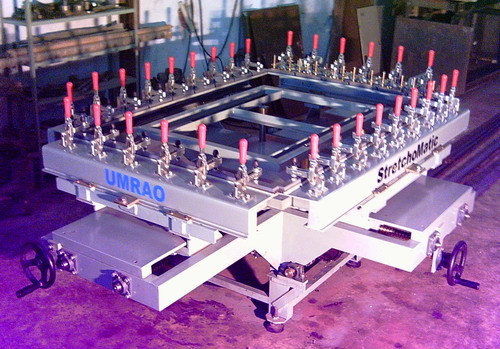

Fabric Stretching Machine

Price 415000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Size : 48

Computerized : Yes

Type : Other

Warranty : One Year

Economical Stretching Machine

Price 125000 INR / Unit

Minimum Order Quantity : 1 Inch

Size : 20

Computerized : Yes

Type : Economical Stretching Machine

Warranty : One Year

Squeegee Sharpener

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Sizes Available

Computerized : Yes

Type : Sqeezee Sharpner

Warranty : 1 Year

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free