Roll To Roll Screen Printing Machine

Price 1950000 INR/ Unit

Roll To Roll Screen Printing Machine Specification

- Type

- Roll to Roll Printing Machine

- Material

- High-Grade Steel and Aluminum

- Capacity

- 2000 Impressions/hr Kg/hr

- Printing Speed

- 2000 Impressions/hr mm/m

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Screen Plate

- Print Direction

- Unidirectional & Bidirectional

- Ink Type

- UV, Solvent, Water-Based

- Color Management

- CMYK/RGB Supported

- Control System

- PLC Touchscreen Control

- Working Temperature

- 15C - 35C

- Power

- 220V/380V, 3 Phase, 2.5 kW

- Size

- Standard, Customizable

- Width

- Up to 1200 mm

- Weight (kg)

- 1500

- Dimension (L*W*H)

- 3200mm x 1500mm x 1650mm

- Drying System

- Hot Air / IR Dryer Integrated

- Feeding System

- Automatic Unwinder and Rewinder

- Noise Level

- <68 dB

- Substrate Thickness

- 30 - 300 micron

- Maximum Roll Diameter

- 400 mm

- Air Pressure Requirement

- 6-8 Bar

- Maintenance

- Low, Easy Access

- Safety Features

- Emergency Stop, Overload Protection

- Operator Interface

- Digital LCD Display

- Registration Accuracy

- ±0.15 mm

Roll To Roll Screen Printing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 3 Units Per Month

- Delivery Time

- 1 Week

- Packaging Details

- As per customer requirement

- Main Export Market(s)

- Western Europe, Asia, Australia, North America, Middle East, Central America, Eastern Europe, South America, Africa

- Main Domestic Market

- Jammu and Kashmir, Himachal Pradesh, Meghalaya, Pondicherry, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, South India, West India, Jharkhand, Odisha, Tamil Nadu, Maharashtra, Andaman and Nicobar Islands, Chandigarh, Telangana, East India, Goa, Rajasthan, Bihar, Manipur, Kerala, Arunachal Pradesh, Tripura, West Bengal, Andhra Pradesh, Mizoram, Sikkim, Assam, Central India, Chhattisgarh, Haryana, Gujarat, Delhi, Madhya Pradesh, Karnataka, North India, Punjab, Uttar Pradesh, All India

About Roll To Roll Screen Printing Machine

We are offering roll to roll printing machines that are fabricated in compliance with international quality standards using latest technology. These machines are suitable for printing on any roll form such as pvc, soft plastic circuit, heat transfer paper and polyester. Branded parts and five-phase stepping motor are used to ensure smooth and stable run and to achieve maximum printing accuracy. We can also provide customization as required by the client.

Suitable for printing continuously on any roll form such as pvc, opp, polyester, heat transfer paper, and soft plastic circuit plate. Controlled by advanced computer system; driven by japanese brand-named 5-phase stepping motor to achieve maximum accuracy of printing. Brand-named pneumatic parts are used. Precise shafts and bearings are placed in active parts of the machine to ensure smooth and stable runs. Programmable plc system is built into the machine so that printing programs can be changed easily.

Precision and Versatility for Industrial Printing

Designed for use within diverse industrial environments, the Roll To Roll Screen Printing Machine offers unmatched accuracy, printing speed, and compatibility with multiple ink types, including UV, water-based, and solvent inks. Its advanced PLC touchscreen and CMYK/RGB color management system enable user-friendly operation, while its wide substrate thickness range allows application versatility across packaging, graphics, and specialty print production.

Integrated Safety and Effortless Maintenance

Operator security is ensured through vital safety features such as emergency stop buttons and overload protection. The machine is constructed for low-maintenance upkeep and easy accessibility, providing steady productivity with minimal downtime. Digital LCD displays further support efficient monitoring and operation, while a quiet operating level below 68 dB maintains a comfortable workspace.

FAQs of Roll To Roll Screen Printing Machine:

Q: How does the Roll To Roll Screen Printing Machine ensure precise registration during operation?

A: The machine achieves a high registration accuracy of 0.15 mm by utilizing advanced mechanical design, computerized controls, and stable feeding systems that keep the substrate consistently aligned during fast-paced printing.Q: What materials and ink types can be used with this machine?

A: Its compatible with flexible substrates from 30 to 300 microns thick, such as films and foils. The system supports UV, solvent, and water-based inks, allowing for a range of applications from packaging to graphics.Q: When is the integrated drying system activated during the printing process?

A: The hot air/IR dryer automatically operates in sync with the printing process, ensuring each impression is adequately dried for high-speed output and superior print quality.Q: Where is the Roll To Roll Screen Printing Machine typically installed and utilized?

A: Commonly found in manufacturing facilities and print production plants, the machine is suited for settings requiring continuous, large-scale roll-based printing with precise registration and color management.Q: What is the operational process from roll loading to final rewinding?

A: The substrate roll is loaded onto the automatic unwinder, passes through precise registration and the screen printing unit, then dries via the integrated hot air/IR dryer before being neatly rewound by the automated rewinder system.Q: How does the user interface simplify operation and monitoring of the machine?

A: A digital LCD display and PLC touchscreen provide intuitive access to controls, real-time status updates, and easy adjustments, enhancing operational efficiency and minimizing the learning curve for operators.Q: What benefits does this machine offer regarding productivity and maintenance?

A: With a capacity of 2000 impressions per hour, low noise emissions, automated feeding, robust safety features, and easy-access maintenance design, users experience enhanced productivity and reduced downtime, supporting high-efficiency production environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Printing Press Machine Category

Textile Curing Machine

Price 370000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Type : Textile Curing Machine

Size : 25

Automatic Grade : SemiAutomatic

Computerized : No

Balloon Screen Printing Machine

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Balloon Printing Machine

Size : 150 X 150mm

Automatic Grade : SemiAutomatic

Computerized : Yes

Roll to Roll Automatic Screen Printing Machine

Price 1960000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Roll to Roll Screen Printing Machine

Size : 08

Automatic Grade : Automatic

Computerized : Yes

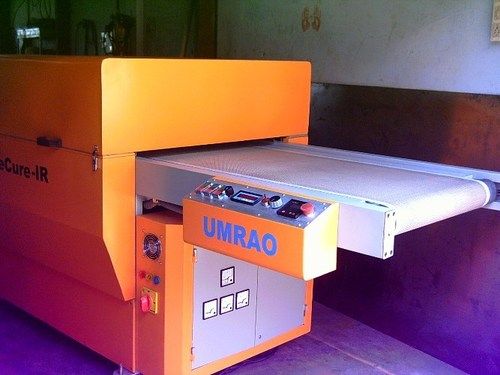

Infrared Curing Machine

Price 470000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : IR Dryer

Size : 25

Automatic Grade : Automatic

Computerized : Yes

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free