Emulsion Coating Machine

Price 420000.0 INR/ Piece

Emulsion Coating Machine Specification

- Product Type

- Automatic Emulsion Coating Machine

- General Use

- Industrial

- Weight (kg)

- 275 Kilograms (kg)

- Coating Head

- Other

- Coating Width

- 38 Inch (in)

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Power Source

- Electric

- Dimension (L*W*H)

- 65 Inch (in)

- Feature

- Low Energy Consumption, High Speed, Printing

- Warranty

- One Year

Emulsion Coating Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 2 Pieces Per Month

- Delivery Time

- 3 Week

- Packaging Details

- As per customer requirement

- Main Domestic Market

- All India, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Nagaland, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Emulsion Coating Machine

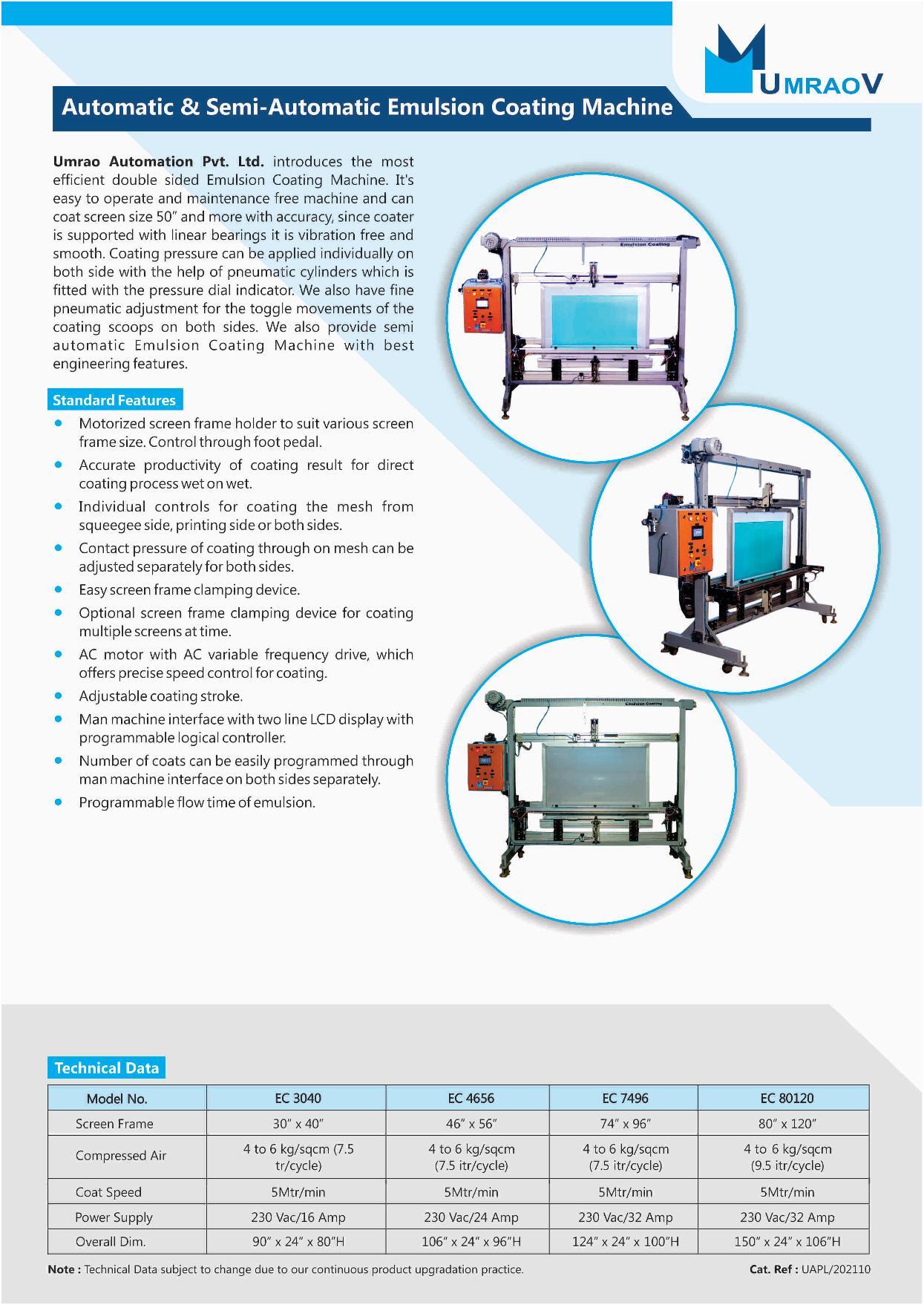

Umrao Automation Pvt. Ltd. introduces the most efficient double sided Emulsion Coating Machine. Its easy to operate and maintenance free machine and can coat screen size 50 and more with accuracy, since coater is supported with linear bearings it is vibration free and smooth. Coating pressure can be applied individually on both sides with the help of pneumatic cylinders which is fitted with the pressure dial indicator. We also have fine pneumatic adjustment for the toggle movements of the coating scoops on both sides. We also provide semi automatic Emulsion Coating Machine with best engineering features.

Standard Features

Motorized screen frame holder to suit various screen frame size. Control through foot pedal.

Accurate productivity of coating result for direct coating process wet on wet.

Individual controls for coating the mesh from squeezee side, printing side or both sides.

Contact pressure of coating through on mesh can be adjusted separately for both sides.

Easy screen frame clamping device.

Optional screen frame clamping device for coating multiple screens at time.

AC motor with AC variable frequency drive, which offers precise speed control for coating.

Adjustable coating stroke.

Man machine interface with two line LCD display with programmable logical controller.

Number of coats can be easily programmed through man machine interface on both sides separately.

Programmable flow time of emulsion.

Specifications

|

Minimum Order Quantity |

1 Piece |

|

Design Type |

Customized |

|

Frame Size |

48" x 64" |

|

Machine Size |

65" L x 21" W X 72" H |

|

Weight |

275 kg |

|

Electric Power |

2 kW |

|

Attribute |

Faster make easy |

|

Print Quality |

High |

Advanced PLC-Controlled Automation

This emulsion coating machine integrates a sophisticated PLC control system, enabling seamless, computerized operation. The automation not only boosts throughput but also ensures precise coating every cycle, making it a smart choice for demanding industrial environments.

Energy Efficient and High-Speed Performance

Featuring low energy consumption and high-speed coating capabilities, this machine provides significant operational savings without compromising on productivity. Its reliable electric power source contributes to environmentally responsible manufacturing processes.

Designed for Industrial Versatility

With a 38-inch coating width and a sturdy construction weighing 275 kilograms, this emulsion coating machine accommodates various industrial coatings and printing requirements. Its versatility and automatic features make it ideal for manufacturers, exporters, and suppliers.

FAQs of Emulsion Coating Machine:

Q: How does the computerized PLC control system enhance the operation of the emulsion coating machine?

A: The PLC control system automates key functions, enabling precise and consistent coating application. It reduces manual intervention, minimizes errors, and allows operators to manage settings easily, improving both productivity and coating quality.Q: What processes can be handled by this emulsion coating machine?

A: This machine is suitable for various industrial coating and printing processes, providing a uniform emulsion layer over surfaces up to 38 inches wide. It is ideal for applications that demand speed, consistency, and high-quality results.Q: When is preventive maintenance recommended for this machine?

A: Regular preventive maintenance checkstypically every three to six months or based on usagewill help ensure optimal performance, reduce downtime, and extend the overall service life of the equipment.Q: Where can the emulsion coating machine be installed for optimal performance?

A: Installation in a clean, industrial space with stable electric power access is recommended. Adequate ventilation and flat flooring support safe operation and consistent output quality.Q: What are the primary benefits of using this emulsion coating machine in industrial settings?

A: Key benefits include automated, high-speed coating, reduced energy consumption, enhanced coating precision, and the ability to process wide materials. Its robust design and warranty make it a reliable investment for businesses.Q: How is the machine typically used in a production workflow?

A: Operators can quickly set up desired coating parameters through the intuitive computerized interface, start the automatic coating process, and monitor production. The systems PLC controls manage speed, layer thickness, and workflow seamlessly.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry