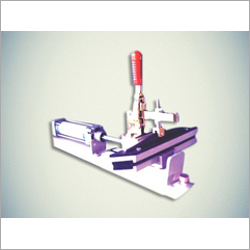

Pneumatic Fabric Stretching Clamps

Price 17000 INR/ Unit

Pneumatic Fabric Stretching Clamps Specification

- Tensile Strength

- High (suitable for fabric tensioning)

- Weight

- 1.2 kg

- Material Grade

- SS304

- Density

- 7.85 Gram per cubic centimeter(g/cm3)

- Metal Type

- Steel

- Material

- Metal

- Usage

- Stretch

- Structure

- Clamp-type mechanism

- Size

- 10"

- Standard

- Industrial grade

- Shape

- Rectangular jaws

- Color

- Silver

- Application

- Screen printing and textile stretching

- Max Fabric Thickness

- 5 mm

- Surface Finish

- Polished

- Connection Type

- Air inlet (standard fitting)

- Corrosion Resistance

- Yes

- Jaw Width

- 75 mm

- Mounting

- Manual or machine compatible

- Grip Mechanism

- Rubber-padded jaws

- Operating Pressure

- 0.4 - 0.8 MPa

Pneumatic Fabric Stretching Clamps Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque, Telegraphic Transfer (T/T), Western Union, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 3 Units Per Day

- Delivery Time

- 5-6 Days

- Packaging Details

- wooden packing

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, South America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Nagaland, Uttarakhand, Daman and Diu, All India, Lakshadweep, Meghalaya, Sikkim, Rajasthan, West Bengal, Arunachal Pradesh, Telangana, Chandigarh, Manipur, Andaman and Nicobar Islands, Haryana, Pondicherry, East India, Maharashtra, Madhya Pradesh, Karnataka, Assam, Jharkhand, Tripura, Goa, Mizoram, Delhi, South India, Punjab, Gujarat, Bihar, Jammu and Kashmir, Uttar Pradesh, Tamil Nadu, North India, Andhra Pradesh, Kerala, Central India, Odisha, West India, Chhattisgarh

About Pneumatic Fabric Stretching Clamps

Umrao Automation Pvt.Ltd Pneumatic Fabric stretching system is designed to meet high end fabric tension requirements in screen printing industry. ST 200/ ST 250 are two models available.We offer pneumatic fabric stretching clamp of fabric that provides easy and powerful clamping of fabric. Fabricated using quality tested raw material, the stretching clamp is composed of fabric gripping with double groove rubber lining jaw of length 250 mm. It had adjustable frame leveling screw for individual clamp and also has the feasibility to arrange multiple clamps of any size of frame.

Standard Features :

- Pneumatic cyclinder of 40 mm bore dia. with 100 mm stroke length.

- Stretching capacity up to 42 N possible.

- Screen fabric holder (jaws) with silicone rubber holders.

- Specially designed extruded wear-resistant rubber to prevent fabric slippage.

- Available in 8" & 10" jaw width to suit various frame size.

- Adjustable frame leveling screw leveling screw for individual clamp.

Technical Specification :

| Model | ST 200 | ST 250 |

| Clamping Jaw with | 200 mm | 250 mm |

| Stroke | 100 mm | 100 mm |

| Air pressure | Max. 10 kg/ Sq. Cm. | Max. 10 kg/ Sq. Cm. |

| Length of unit | 500 mm | 500 mm |

Unmatched Performance and Versatility

Designed specifically for textile stretching and screen printing, these pneumatic clamps offer a robust grip with their high-tensile, steel structure, and rubber-padded jaws. Their compatibility with both manual and automated machine setups ensures seamless integration into diverse industrial environments.

Premium Materials and Build Quality

Crafted from SS304 grade stainless steel with a density of 7.85 g/cm, our clamps feature a polished surface and are highly resistant to corrosion, guaranteeing a long service life and optimal performance under rigorous conditions.

Effortless Operation and Mounting

Engineered for ease of use, these clamps connect easily via standard air fittings and deliver consistent tension using a pneumatic mechanism. The manual or machine mounting flexibility caters to differing workspace requirements, making them a preferred choice in professional fabric tensioning operations.

FAQs of Pneumatic Fabric Stretching Clamps:

Q: How do I operate the pneumatic fabric stretching clamps?

A: To operate the clamps, connect them to an air compressor through the standard air inlet. Adjust the pressure within the 0.40.8 MPa range to achieve the desired tension. The rubber-padded jaws can be manually or machine-mounted, making the process effortless and efficient for fabric stretching.Q: What are the main benefits of using these clamps for screen printing?

A: These clamps provide uniform tension with high tensile strength, preventing fabric slippage or damage. Their corrosion-resistant SS304 steel build and polished finish ensure durability, while the rubber-padded jaws protect delicate textiles, making them ideal for precise screen printing or textile applications.Q: When should these clamps be used in textile operations?

A: Use these clamps whenever consistent, high-tension fabric stretching is required, such as during screen printing setup or textile preparation, especially with fabrics up to 5 mm thick. Their robust design is suitable for both initial stretching and maintaining tension during processing.Q: Where can these clamps be mounted or utilized?

A: These clamps are versatile and can be mounted on both manual frames and automated machines. Their design allows for effective use in workshops, textile factories, or print facilities where reliable fabric tensioning is critical.Q: What types of fabrics are compatible with the clamps?

A: The clamps are suitable for most standard textiles used in screen printing, provided the thickness does not exceed 5 mm. The jaws rubber padding ensures a gentle grip, accommodating a range of fabric types without causing tears or deformation.Q: What process should be followed after mounting the clamps?

A: Once the clamps are securely mounted and connected to the air supply, gradually increase the operating pressure until the desired fabric tension is reached. Periodically check for consistent grip and adjust pressure as needed to maintain optimal results throughout the process.Q: How does the clamps surface finish and material contribute to its durability?

A: The polished finish on high-grade SS304 steel offers superior corrosion resistance and minimizes wear, ensuring that the clamp remains reliable and effective even after prolonged use in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry