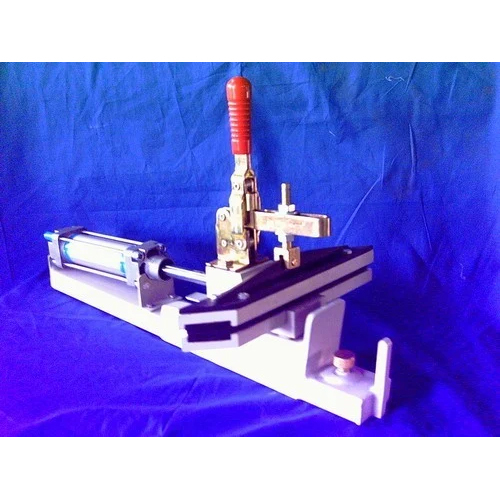

Pneumatic Fabric Stretching Clamp

Price 2000 INR/ Piece

Pneumatic Fabric Stretching Clamp Specification

- Frequency

- 50 Hz / 60 Hz Hertz (HZ)

- Hook

- Integrated Stainless Steel Hook

- Product Type

- Pneumatic Fabric Stretching Clamp

- Material

- Stainless Steel

- Machinery Type

- Automatic Clamping Equipment

- Voltage

- 220V / 380V Volt (v)

- Power

- 0.5 kW Watt (w)

- Dimension (L*W*H)

- 500 mm Millimeter (mm)

- Weight

- Approx. 7 kg Kilograms (kg)

- Color

- White

- Control

- Manual/Foot Pedal

- Surface Treatment

- Polished Steel

- Grip Strength

- Strong Non-slip Clamping

- Nozzle Material

- High-Grade Brass

- Safety Feature

- Pressure Relief Valve Included

- Mounting Type

- Bench/Frame Mount

- Operating Method

- Pneumatic (Air Assisted)

- Application

- Textile Screen Printing Fabric Stretching

- Clamping Width

- 50 150 mm

- Air Pressure Requirement

- 0.60.8 MPa

Pneumatic Fabric Stretching Clamp Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 7 Days

About Pneumatic Fabric Stretching Clamp

Specifications

| Minimum Order Quantity | 1 Piece |

| Brand | Umrao Automation Pvt. Ltd. |

| Material | Stainless Steel |

| Compressed Air Pressure | 10 kg/sq. cm |

| Diameter | 100 mm |

| Size/Dimension | 500 mm |

| Stretching Capacity | Up to 42 n |

| Holder | Silcone Rubber |

| Length | 250 mm |

Effortless Fabric Stretching for Screen Printing

This pneumatic clamping equipment streamlines the process of stretching fabric onto screen printing frames. Leveraging reliable air-assisted mechanics, it delivers strong, non-slip grip and consistent results every time. Its stainless steel construction and polished surface enhance longevity, while its customizable design can adapt to specific production lines.

Enhanced Operator Safety and Efficiency

Equipped with a pressure relief valve, the clamp prioritizes operator safety, preventing over-pressurization during operation. Users can easily shift between manual and foot pedal controls for convenient handling, making it perfect for both large-scale and small-batch textile printing environments.

FAQs of Pneumatic Fabric Stretching Clamp:

Q: How does the pneumatic fabric stretching clamp operate?

A: The clamp uses compressed air (0.60.8 MPa) to generate strong, consistent pressure for securing fabric onto a screen printing frame. Operators can control the mechanism using either a manual handle or a foot pedal, making the stretching process efficient and hands-free.Q: What types of fabric can this clamp handle during the stretching process?

A: This equipment accommodates a range of textile fabrics, including mesh and synthetic materials commonly used in screen printing. The wide clamping width (50150 mm) and non-slip grip ensure even delicate or slippery fabrics are securely stretched.Q: When should the pressure relief valve be used?

A: The pressure relief valve automatically activates if the system exceeds safe air pressure limits, safeguarding both the equipment and users. Regular checks ensure it remains functional, especially before intense or continuous use.Q: Where can the pneumatic clamp be installed or mounted?

A: The clamp is designed for versatile mounting, suitable for both bench and frame installations. This flexibility allows seamless integration into existing workshop setups or dedicated screen printing stations.Q: What are the benefits of using this automatic clamping equipment in textile production?

A: Key benefits include faster fabric preparation, uniform stretching, reduced labor effort, and minimized risk of slippage or fabric damage. Its stainless steel body and advanced safety measures contribute to long-term reliability and safe operation.Q: How is the grip strength maintained during operation?

A: The clamps pneumatic system evenly distributes pressure along the fabric edge, and its robust, non-slip jaws ensure the fabric remains taut and secure, even under tension changes or during long production runs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fabric Stretching Machines Category

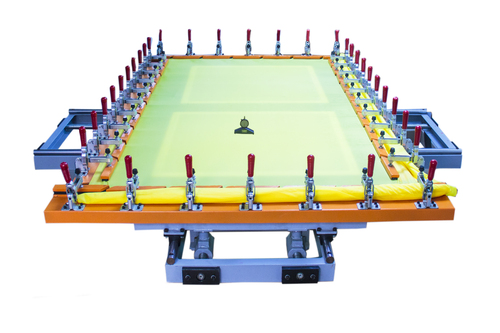

Fabric Stretching Machine

Price 440000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Multicolour

Weight : 550 Kilograms (kg)

Product Type : Other

Dimension (L*W*H) : 66"x96"x35" Inch (in)

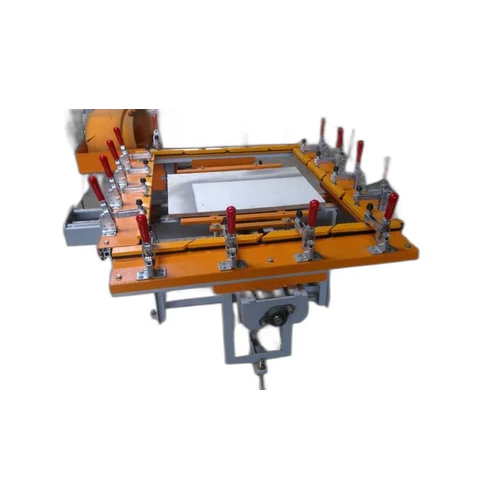

Mechanical Stretching Machines

Price 180000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Blue & Silver

Weight : 170 Kilograms (kg)

Product Type : Other

Dimension (L*W*H) : 1800 x 1200 x 1600 mm

Mechanical Stretching Machines 15x20

Price 175000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Orange

Weight : Approx. 90 kg

Product Type : Other, Mechanical Stretching Machines

Dimension (L*W*H) : Approx. 28 x 34 x 50 inches

Fabric Stretching Clamp

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : White

Weight : 0.35 kg

Product Type : Other

Dimension (L*W*H) : 250mm x 40mm x 40mm

Send Inquiry

Send Inquiry