Welcome to Our Company

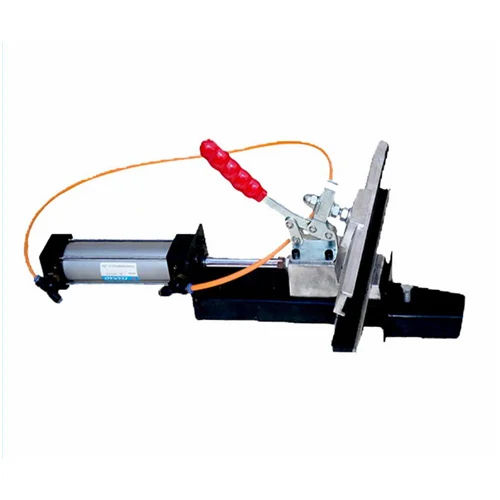

Pneumatic Stretching Clamps

Price 1250 INR/ Piece

MOQ : 1 Piece

Pneumatic Stretching Clamps Specification

- Material Grade

- Premium

- Metal Type

- Steel

- Density

- 7.85 Gram per cubic centimeter(g/cm3)

- Weight

- Approx. 1.2 kg Kilograms (kg)

- Usage

- Industrial

- Material

- Other

- Structure

- Clamp

- Standard

- Industrial

- Product Type

- Pneumatic Fabric Stretching Clamp

- Shape

- Rectangular

- Color

- Black

- Length

- 275 mm Millimeter (mm)

Pneumatic Stretching Clamps Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 7 Days

About Pneumatic Stretching Clamps

Specifications

| Minimum Order Quantity | 1 Piece |

| Brand | Umrao Automation Pvt. Ltd. |

| Material | Stainless Steel |

| Compressed Air Pressure | 10 kg/sq. cm. |

| Diameter | 40 mm |

| Length | 275 mm |

| Stretching Capacity | Up to 42 n |

| Holder | Silcone Rubber |

Precision and Durability in Industrial Applications

These clamps combine a high-strength, coated steel structure with a premium finish to ensure both toughness and corrosion resistance. The automatic operation and rubberized handle enhance safety and efficiency for industrial users.

Simple and Efficient Operation

Operating at 6-8 bar of pressure, the pneumatic mechanism guarantees secure stretching and clamping with minimal manual intervention, enabling faster throughput on the production floor.

FAQs of Pneumatic Stretching Clamps:

Q: How do I install the pneumatic stretching clamp on a bench?

A: The clamp features a bench-mounted design, allowing you to secure it directly to your workbench using bolts. Ensure the surface is stable and follow the installation guide provided for optimal alignment.Q: What is the recommended operating pressure for this clamp?

A: These clamps are designed to operate efficiently at a pressure between 6 to 8 bar, delivering reliable clamping force while safeguarding the internal mechanisms.Q: When should this clamp be used over manual alternatives?

A: This pneumatic clamp is ideal when consistent and high-tension clamping is required, especially for repetitive industrial tasks that benefit from automation, speed, and uniform gripping force.Q: Where can these clamps be utilized in manufacturing processes?

A: They are suited for textile stretching, assembly lines, fabrication, and various other industrial environments where stable, precise clamping is essential.Q: What are the main benefits of the rubberized handle?

A: The rubberized handle increases grip comfort and slip resistance, reducing operator fatigue and enhancing safety during repetitive tasks.Q: How does the corrosion-resistant coating extend the life of the clamp?

A: The coated surface protects the steel body from exposure to moisture and chemicals, minimizing rust and wear even in demanding industrial environments.Q: What process should be followed for routine maintenance?

A: Regularly check the pneumatic connections for leaks, clean the exterior to remove dust or residue, and occasionally lubricate the moving parts as outlined in the maintenance manual for peak performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry