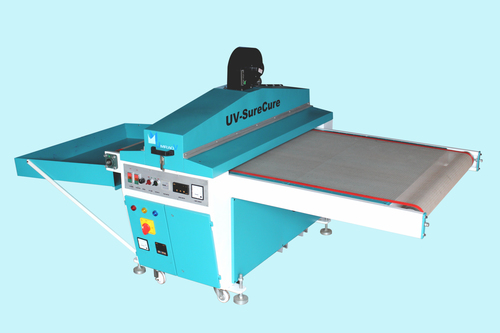

Uv Curing Dryer

Price 370000 INR/ Unit

Uv Curing Dryer Specification

- Type

- Curing Machine

- Computerized

- Yes

- Automatic Grade

- Automatic

- Print Direction

- Other

- Ink Type

- UV Curing Ink

- Color Management

- Other

- Power

- 430 VAC Volt (v)

- Size

- 16

- Width

- 16 Inch (in)

- Warranty

- One Year

Uv Curing Dryer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 4 Units Per Month

- Delivery Time

- Week

- Packaging Details

- As per Customer requirement

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Madhya Pradesh, Goa, Manipur, Sikkim, Assam, West India, Tamil Nadu, Maharashtra, West Bengal, Delhi, Rajasthan, Arunachal Pradesh, Jammu and Kashmir, Punjab, Jharkhand, Gujarat, Telangana, South India, East India, Mizoram, Tripura, Meghalaya, Chandigarh, Bihar, Haryana, Karnataka, North India, Uttar Pradesh, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

About Uv Curing Dryer

Uv Curing Dryer

Ultra Violet Curing Machine is built with our 17 years of experience in UV Curing technology. Engineered for high speed UV curing of vinyl, polyesters, metals, papers & other heat sensitive substrates. The dual blower cooling system minimizes heat transmission to stock. Our ozone/hot air removal system exhausts ozone & hot air from the heat source & helps to keep cool printing shop.

- Compact and designed machine fabrication.

- Heavy duty castor wheels for easy with foundation bolts for leveling.

- Medium pressure mercury vapour UV lamps 400 watts/inch can also be run at 250 watts/inch for low production speed if required.

- Individual lamp control with separate heavy duty transformer and capacitor bank.

- Anti-Static PTFE coated fiber glass conveyor belt.

- Conveyor driven by pre lubricated AC geared motor(Imported)

- AC frequency inverter for infinite speed if control.

- Digital belt speed indicator in M/Min.

- Safety switched for reflectors.

- Specially designed elliptical UV irradiators.

- Heavy duty switch-gears designed using constant wattage technology.

- Lampa are protected with miniature circuit breakers for over load special extended conveyors as per requirements and applications.

Advanced UV Curing Technology

This curing machine utilizes innovative UV curing technology to instantly dry UV inks. It improves productivity by enabling faster processing and minimal waiting periods between printing and finishing. With a 16-inch operational width, it fits seamlessly into both small and large-scale production environments.

Automatic and Computerized Efficiency

Equipped with automatic grade and computerized controls, this dryer guarantees consistent results with minimal manual intervention. Operators benefit from precise settings, programmability, and reduced susceptibility to human error, resulting in consistent, high-quality output every time.

FAQs of Uv Curing Dryer:

Q: How does the UV Curing Dryer work for UV curing ink?

A: The UV Curing Dryer uses powerful UV lamps to instantly cure UV curing inks applied to substrates. When the ink passes through the dryer, exposure to ultraviolet light causes rapid polymerization, resulting in a dry and durable finish within seconds.Q: What are the benefits of using this automatic and computerized curing machine?

A: This automatic, computerized curing machine enhances production speed and consistency while minimizing the risk of errors. It allows for precise control over curing parameters, reducing energy consumption and ensuring uniform ink curing across all material surfaces.Q: When should I use a UV Curing Dryer in my printing process?

A: You should use the UV Curing Dryer after printing with UV curing ink to instantly cure and set the ink, ensuring durability and preventing smudging or transfer. It is essential for any industrial application where immediate handling and high-quality finishing are required.Q: Where can this UV Curing Dryer be installed?

A: The UV Curing Dryer is designed for installation in industrial printing facilities, packaging centers, and manufacturing units of various sizes. Its compact form factor and 16-inch operational width make it suitable for integration into different production lines.Q: What is the process for operating the UV Curing Dryer?

A: To operate the UV Curing Dryer, simply load your printed materials onto the conveyor system, set the computerized controls to match your curing requirements, and let the automatic system process the items. The dryer ensures rapid and uniform curing as materials pass beneath the UV lamps.Q: How long is the warranty for this UV Curing Dryer?

A: We offer a one-year warranty on this UV Curing Dryer, covering defects in materials and manufacturing. This ensures confidence and reliability in your investment.Q: What makes this UV Curing Dryer suitable for exporters, manufacturers, and suppliers in India?

A: As a product engineered and supplied in India, this curing machine complies with industrial standards and is designed to meet the needs of local exporters, manufacturers, and suppliers. Its robust build, reliable performance, and efficient operation support high-volume production and quality assurance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Post Press Machine Category

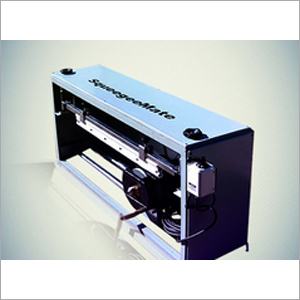

Automatic Squeegee Sharpener

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 115120 Volt (v)

Computerized : No

Automatic Grade : Automatic

Size : 80

UV IR Combo Curing Unit

Price 390000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 440 VAC Siemens Volt (S )

Computerized : Yes

Automatic Grade : Automatic

Size : 16

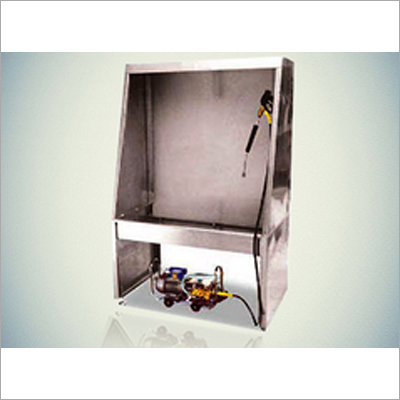

Washing Tank with Back Light

Price 375000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 230 VAC Volt (v)

Computerized : No

Automatic Grade : Manual

Size : 30

Infra Red Curing Machine

Price 550000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 380 Volt (v)

Computerized : Yes

Automatic Grade : Automatic

Size : 16

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free