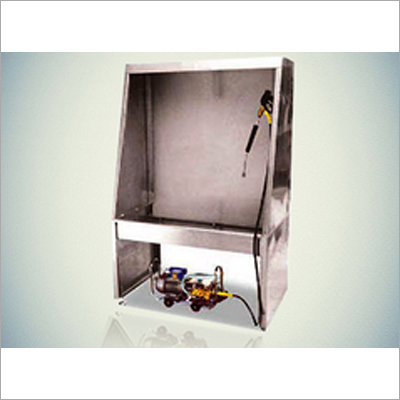

Washing Tank with Back Light

Price 375000 INR/ Unit

Washing Tank with Back Light Specification

- Type

- Washing Booth

- Computerized

- No

- Automatic Grade

- Manual

- Plate Type

- Other

- Print Direction

- Other

- Ink Type

- Other

- Color Management

- Other

- Power

- 230 VAC Volt (v)

- Size

- 30

- Warranty

- One Year

Washing Tank with Back Light Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Western Union, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1-2 Week

- Packaging Details

- wooden packing

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Lakshadweep, Goa, Punjab, South India, Assam, Delhi, West India, Meghalaya, Sikkim, Tamil Nadu, Telangana, East India, Jammu and Kashmir, Bihar, Mizoram, Arunachal Pradesh, Jharkhand, Tripura, West Bengal, Madhya Pradesh, Chandigarh, Maharashtra, Pondicherry, Karnataka, Rajasthan, Manipur, Nagaland, Haryana, Gujarat, Uttar Pradesh, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

About Washing Tank with Back Light

Washing Tank with Back Light

The offered Washing Tank with Back Light is especially designed to wash the print screens for better finish or to increase the quality. It is closed chamber which is fabricated by using premium grade steel provided with a fine galvanized coating to prevent any damage due to moisture and due to the impacts of various chemicals for the prevention of corrosion. It is also provided with a proper drainage system to avoid water clogging.

Screen plays an important role in screen printing technology. Improper washing system and inadequate light causes higher percentage of rejection of screens. Considering the above factors in mind ultracuring system introduces screen washing tank with back light system. The complete body of the tank is made of stainless steel (ss-304) to avoid corrosion. Galvanized bodied economical models and also available. Yellow back-light prevents pre exposure of the stencil while washing the screen & eliminates the chances of ghost image been left due to insufficient light.

- Stainless steel (ss 304) construction helps to work with all kind of chemical generally used in screen reclaiming and avoids corrosion.

- Yellow back-light avoids pre exposure while wahsing the screen

- Good drainage suystem ensures no water and any residues left in the tank.

- Recycling washing liquid tank(optional)

Enhanced Visibility With Back Light

The integrated back light in the washing tank provides superior illumination, making inspection and cleaning tasks more precise. This feature reduces the chances of missing residual particles, improving the overall efficiency of washing operations in your facility.

Durable Manual Operation

Designed with manual controls, this washing booth offers straightforward usage without the complexities of computerized systems. Its simple interface ensures quick learning for operators and reduces the risk of technical malfunctions.

FAQs of Washing Tank with Back Light:

Q: How does the back light feature in the washing tank improve the cleaning process?

A: The back light enhances visibility inside the tank, allowing operators to spot and remove any debris or residues effectively, leading to a thorough and more reliable cleaning process.Q: What are the primary uses for this manual washing booth?

A: This washing tank is mainly used for washing components or equipment in industrial and commercial environments where manual cleaning is required. It is suitable for tasks where precision and careful inspection are important.Q: When should routine maintenance of the washing booth be performed?

A: Routine maintenance should be completed according to the manufacturers recommendations or at least quarterly to extend the products lifespan. Regular checks ensure the tank and back light remain in optimal condition.Q: Where is this washing tank manufactured and supplied from?

A: We manufacture and supply the washing tank from our facilities in India, serving both domestic and international clients as an exporter, manufacturer, and supplier.Q: What is the typical process for using the washing booth?

A: To use the washing booth, simply place the item inside, utilize the back light to inspect thoroughly, and manually wash the item as required. The user-friendly design allows for precise manual cleaning.Q: What are the key benefits of choosing this non-computerized washing booth?

A: With no computerized components, the washing booth is easy to operate, low-maintenance, and less prone to technical failures. This results in reduced operational costs and dependable performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Post Press Machine Category

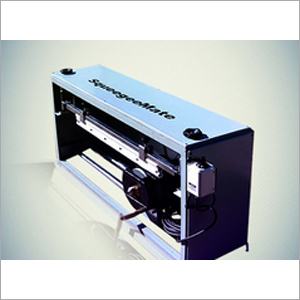

Automatic Squeegee Sharpener

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : No

Width : 25cm

Power : 115120 Volt (v)

UV IR Combo Curing Unit

Price 390000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : Yes

Width : 16 Inch (in)

Power : 440 VAC Siemens Volt (S )

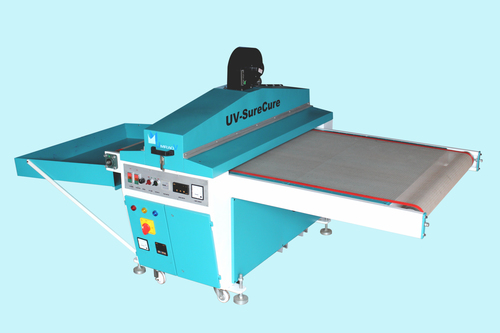

Uv Curing Dryer

Price 370000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : Yes

Width : 16 Inch (in)

Power : 430 VAC Volt (v)

Infra Red Curing Machine

Price 550000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : Yes

Width : 16 Inch (in)

Power : 380 Volt (v)

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free