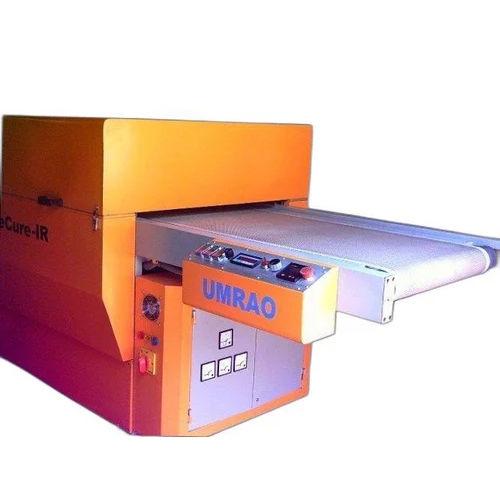

IR Curing Machine 20

Price 395000 INR/ Piece

IR Curing Machine 20 Specification

- Power

- 380 V Volt (v)

- Usage

- Industrial

- Material

- Iron

- Voltage

- 380 V Volt (v)

- Size

- 20

- Product Type

- IR Curing Machine

- Color

- Orange

IR Curing Machine 20 Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cheque, Cash on Delivery (COD)

- Delivery Time

- Days

- Packaging Details

- As per customer requirement

- Main Domestic Market

- North India, East India, Gujarat, Central India, Karnataka, Dadra and Nagar Haveli, Nagaland, Rajasthan, Sikkim, Telangana, Andhra Pradesh, Haryana, Himachal Pradesh, South India, Lakshadweep, Chandigarh, Goa, West Bengal, Kerala, Mizoram, Daman and Diu, Chhattisgarh, Madhya Pradesh, Tamil Nadu, Tripura, Andaman and Nicobar Islands, Jharkhand, Arunachal Pradesh, Jammu and Kashmir, Maharashtra, Pondicherry, Punjab, Delhi, West India, Meghalaya, Manipur, Uttar Pradesh, Uttarakhand, Odisha, All India, Bihar, Assam

About IR Curing Machine 20

Specifications

| Minimum Order Quantity | 1 Piece |

| Voltage | 380 V |

| Power | 380 V |

| Usage | Drying |

| Size | 20" |

| Power Source | Electrical |

| Model No | US - IR 20 | US- IR 25 | US - IR 30 | US - IR 40 | US - IR 50 |

| Conveyor Width | 20" | 25" | 30" | 40" | 50" |

| Curing Speed | 8-12 Mrt / min | 8-12 Mrt / min | 8-12 Mrt / min | 8-12 Mrt / min | 8-12 Mrt / min |

| Cooling System | Twin Blower Type (Independent blower for suction & delivery) | Twin Blower Type (Independent blower for suction & delivery) | Twin Blower Type (Independent blower for suction & delivery) | Twin Blower Type (Independent blower for suction & delivery) | Twin Blower Type (Independent blower for suction & delivery) |

| Electric Power | 9 KW | 10.5 KW | 12 KW | 14.5 KW | 16 KW |

Superior Industrial Curing Performance

The IR Curing Machine 20 is tailored for industrial settings, offering reliable and uniform heat distribution. This ensures optimized curing for a range of materials, boosting productivity and quality outcomes in manufacturing workflows. Its robust iron build and high voltage operation suit continuous, heavy-duty use.

Sturdy Design with Enhanced Durability

Manufactured with premium iron and coated in orange for visibility and corrosion resistance, this machine is built to last. It embodies a strong industrial aesthetic and withstands rigorous environments, reducing the need for frequent maintenance.

FAQs of IR Curing Machine 20:

Q: How does the IR Curing Machine 20 work in an industrial setting?

A: The IR Curing Machine 20 uses infrared radiation to evenly heat and cure materials in industrial applications. It provides uniform temperature distribution, making it ideal for high-volume curing processes that demand speed and consistency.Q: What materials can be processed with this machine?

A: This machine is suitable for a variety of substrates commonly used in industrial production, including paints, coatings, adhesives, and certain polymers that require controlled curing via infrared heat.Q: When should I use the IR Curing Machine 20?

A: It is recommended to use this machine whenever consistent, efficient, and high-capacity curing is required, particularly in large-scale or continuous production environments.Q: Where can the IR Curing Machine 20 be installed?

A: Designed for industrial facilities, the machine can be installed in manufacturing plants, workshops, and production lines where access to a 380 V power supply is available.Q: What is the process for operating the IR Curing Machine 20?

A: Simply connect the machine to a suitable 380 V electrical source, set the desired operational parameters, and load the materials. The built-in controls allow for fine-tuning to match specific curing requirements.Q: What are the main benefits of using this machine?

A: The primary advantages include efficient energy usage, reduced curing times, improved product quality, durable construction, and suitability for a wide range of industrial applications.Q: Who supplies and exports the IR Curing Machine 20?

A: We are a trusted manufacturer, exporter, and supplier based in India, committed to delivering high-quality industrial curing solutions both domestically and internationally.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in IR Dryers Category

Infra Red Curing Machine (16 Inch)

Price 336000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : One Year

Product Type : Infra Red Curing Machine

Voltage : 380 Volt (v)

Power : 380 V Volt (v)

IR Dryer

Price 350000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Product Type : IR Dryer

Voltage : 230 V Volt (v)

Infrared Flash Cure Dryer

Price 750000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Product Type : Infrared Flash Cure Dryer

Voltage : 380 V Volt (v)

Power : 6 kw Watt (w)

Hot Air Dryer

Price 600000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Product Type : Hot Air Dryer

Voltage : 380 V Volt (v)

Power : 15 kw Watt (w)

Send Inquiry

Send Inquiry