Screen Stretching Machine

Price 410000 INR/ Unit

Screen Stretching Machine Specification

- Type

- Stretching Machine

- Material

- Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Size

- 66 W x 90 L x 35 H

- Weight (kg)

- 550 Kilograms (kg)

- Warranty

- One Year

Screen Stretching Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva

- Supply Ability

- 3 Units Per Month

- Delivery Time

- 2 Week

- Packaging Details

- As per customer requirement

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America

- Main Domestic Market

- Dadra and Nagar Haveli, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Rajasthan, Kerala, Assam, Jammu and Kashmir, Arunachal Pradesh, Andhra Pradesh, South India, Tamil Nadu, Odisha, Himachal Pradesh, East India, Madhya Pradesh, Tripura, Telangana, Haryana, Nagaland, Gujarat, West Bengal, Jharkhand, Meghalaya, North India, Chandigarh, Uttar Pradesh, Delhi, Mizoram, Karnataka, Maharashtra, Punjab, Sikkim, Manipur, Chhattisgarh, Bihar, West India, Goa, Central India, Daman and Diu, Lakshadweep, All India

About Screen Stretching Machine

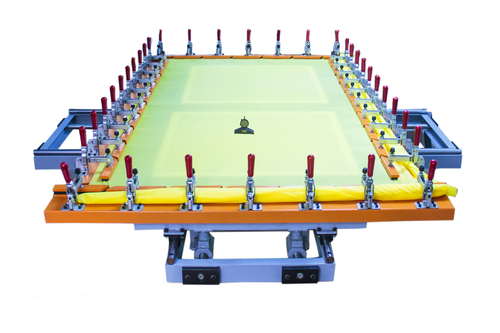

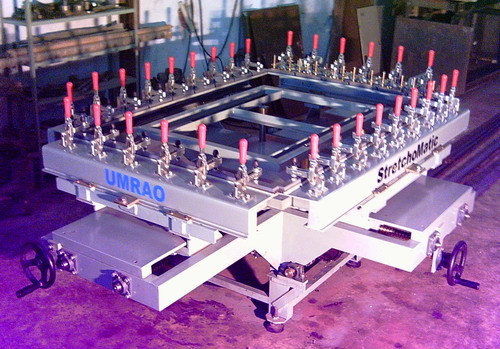

Screen Stretching Machine 48" x 58"

Umrao Automation Pvt.Ltd offers mechanical/ electro-mechanical fabric stretching machine that provides easy and powerful stretching of fabric. fabricated using quality tested raw material, the stretching clamp is composed of fabric gripping with double groove rubber lining jaw of length 250 mm. It had adjustable weft and raft sides. These machines available with motorized controls enable up to stretching 55 N.

Standard features :

- Simultaneous stretching of fabric in four directions.

- Consistent stretching results for years.

- No electricity used, thus lo cost of production ( In manual machines).

- Low maintenance .

- Multiple frames possible.

- facility for frame stretching in angular for CD printing is available.

- Designed to meet tough production requirements.

- Specially designed toggle clap and double V-groove for easy and powerful clamping of fabric.

- Non-slipping silicone rubber grippers used.

Technical Specification :

| Model | Max. Screen Frame (Inch) | Machine size (Inch) | Weight (Approx) kg |

| Strechomatic 4060 | 40 x 60 | 66 W x 90 L x 35 H | 550 |

| Strechomatic 6080 | 60 x 80 | 90 W x 110L x 35 H | 850 |

| Strechomatic 80130 | 80 x 130 | 106 W x 10 L x 35 H | 1500 |

Robust Construction and Design

Manufactured from high-grade steel, the Screen Stretching Machine ensures exceptional durability and performance. Its sturdy frame and significant weight maintain stability during operation, reducing vibration and enhancing accuracy. The generously sized platform supports a range of screen sizes, making it a dependable choice for both small and large-volume tasks in the printing sector.

User-Friendly Semi-Automatic Operation

This machine offers a semi-automatic mechanism, allowing users the flexibility to control key stretching parameters while benefiting from automated assistance. It simplifies the screen stretching process, making it accessible for operators with different skill levels. With no computerized elements, maintenance and troubleshooting are straightforward, which minimizes downtime and costs.

FAQs of Screen Stretching Machine:

Q: How does the semi-automatic Screen Stretching Machine operate?

A: The semi-automatic Screen Stretching Machine combines manual control with automated assistance, enabling users to adjust stretching parameters while the machine handles the tensioning process. This ensures uniform screen stretching and reduces manual effort.Q: What materials are used in the construction of the machine?

A: The machine is constructed entirely from high-quality steel, offering exceptional strength and durability that withstands continuous industrial use.Q: When should you consider using this machine in your production line?

A: This machine is ideal for businesses seeking increased efficiency and consistent results in screen stretching for printing applications. It is especially advantageous during large batch production or when precise tensioning is required.Q: Where can the Screen Stretching Machine be installed?

A: Given its dimensions (66 W x 90 L x 35 H inches) and weight (550 kg), the machine should be installed in a dedicated industrial space or production facility with sufficient floor support and working area.Q: What is the process for stretching screens with this machine?

A: The operator loads the screen onto the platform, secures it, and sets the desired stretching parameters. The semi-automatic mechanism then applies consistent tension, ensuring even stretching across the whole screen.Q: How does using this machine benefit manufacturers and suppliers?

A: Utilizing this screen stretching machine streamlines production, improves screen consistency, reduces manual errors, and ultimately increases output efficiency for manufacturers and suppliers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pre Press Machine Category

Metal Halide Expose Machine

Price 275000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One Year

Type : Metal Halide Expose

Automatic Grade : SemiAutomatic

Computerized : Yes

Fabric Stretching Machine

Price 415000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One Year

Type : Stretching Machine

Automatic Grade : SemiAutomatic

Computerized : Yes

Economical Stretching Machine

Price 125000 INR / Unit

Minimum Order Quantity : 1 Inch

Warranty : One Year

Type : Economical Stretching Machine

Automatic Grade : Manual

Computerized : Yes

Squeegee Sharpener

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Type : Sqeezee Sharpner

Automatic Grade : SemiAutomatic

Computerized : Yes

Send Inquiry

Send Inquiry