Welcome to Our Company

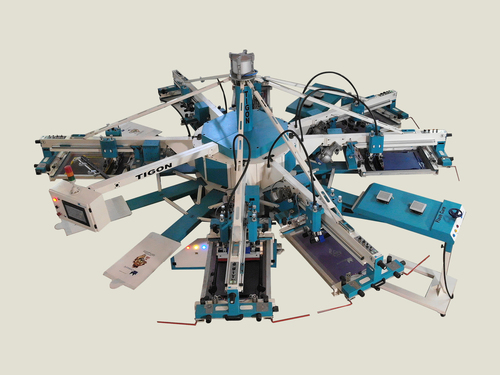

Textile Screen Printing Machine

Price 2500000 INR/ Unit

MOQ : 1 Unit

Textile Screen Printing Machine Specification

- Type

- Textile Screen Printing Machine

- Material

- Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Size

- Sizes Available

- Warranty

- One Year

Textile Screen Printing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Lakshadweep, Nagaland, South India, North India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Odisha, Central India, West India, Chhattisgarh, All India

About Textile Screen Printing Machine

The offered Pneumatic Textile Screen Printing Machine is offered by us that is suitable for use in the various commercial and industrial applications. In screen printing a fine mesh screen made of polyester, nylon, or sometimes metal is stretched over a flat wooden frame, that looks a lot like a picture frame. Printing is the prints on fabric with a combination of design and color. Printing is the process of painting a design drawn by an artist and fixation to the fabric or materials with a mixture of different chemicals and dyes. Pneumatic Textile Screen Printing Machine is very efficient and useful.

Frequently Asked Questions:

1) What is a textile screen printing machine?

A textile screen printing machine is a machine that is used to print designs or patterns onto fabric.

2) How does a textile screen printing machine work?

A textile screen printing machine is a machine that is used to print designs or patterns on textile fabrics. The machine consists of a frame, a screen, and a squeegee. The frame holds the screen in place while the squeegee is used to push the ink through the screen onto the fabric

3) What are the benefits of using a textile screen printing machine?

There are many benefits of using a textile screen printing machine, including the ability to print on a variety of different materials, the ability to print in a variety of different colors, and the ability to print in a variety of different sizes.

4) How can I ensure that my textile screen printing machine is running smoothly?

There are a few things you can do to ensure that your textile screen printing machine is running smoothly. First, make sure that the screen is properly tensioned. Second, make sure that the screen is properly aligned. Third, make sure that the squeegee is properly tensioned.

5) What are some of the most common problems that can occur with textile screen printing machines?

Some of the most common problems that can occur with textile screen printing machines include misaligned screens, improper tension on the screens, and ink buildup on the screens.

Robust and Versatile Printing Solution

Designed for efficiency and durability, this textile screen printing machine is made from high-grade steel and available in several sizes. It is suitable for printing on various textile types, combining ease of use with precision. Its semi-automatic function makes operation manageable, even for users with minimal training, and is ideal for small or growing businesses seeking to broaden their printing capabilities.

Indian Excellence: Exporter and Manufacturer

Manufactured in India, our machine meets international quality standards while offering competitive pricing. We supply to both domestic and global markets, ensuring timely delivery and excellent customer service. As a reliable producer, we also provide comprehensive support and warranty services, making us a preferred choice among textile industry professionals.

FAQs of Textile Screen Printing Machine:

Q: How does a semi-automatic textile screen printing machine operate?

A: This semi-automatic machine requires manual placement of the fabric on the platen but automates stages like ink spreading and screen movement. Operators activate the process with straightforward controls, streamlining printing without needing complex programming.Q: What types of materials can this screen printing machine process?

A: The machine is designed mainly for textile applications and can print on many fabrics including cotton, polyester, silk, and blended textiles. Its adjustable size options ensure versatility across different garment formats.Q: When should I choose a semi-automatic rather than fully automatic or manual machines?

A: Opt for a semi-automatic model when aiming for a balance between production speed and operator control with a moderate investment. It is ideal for small and medium-sized print businesses or for custom orders requiring flexibility.Q: Where is this textile screen printing machine manufactured and supplied from?

A: This machine is manufactured and exported from India. As an established supplier and producer, we deliver both domestically throughout India and internationally to various textile markets.Q: What is the process for installing and maintaining the machine?

A: Installation is straightforward and can be handled by technicians following manufacturer guidelines. Regular cleaning, lubrication of moving parts, and periodic inspection for wear are recommended to ensure reliable operation throughout the warranty period.Q: How can using this machine benefit textile producers?

A: The machine increases productivity and consistency while minimizing manual effort. Its sturdy steel construction prolongs service life, and the one-year warranty provides assurance, making it a cost-effective investment for textile producers seeking quality output.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Printing Press Machine Category

Screen Printing Machine

Price 545000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Warranty : One Year

Automatic Grade : SemiAutomatic

Size : 15"x20"

Roll To Roll 3 Colour With UV Screen Printing Machine

Price 4060000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Warranty : One Year

Automatic Grade : Automatic

Size : 15" x 20"

Roll to Roll Automatic Screen Printing Machine

Price 1960000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Warranty : One Year

Automatic Grade : Automatic

Size : 08

4-Pillar Screen Printing Machine

Price 780000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Warranty : One Year

Automatic Grade : SemiAutomatic

Size : FP2436

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free