Textile Curing Machine

Price 370000 INR/ Unit

Textile Curing Machine Specification

- Type

- Textile Curing Machine

- Material

- Mild Steel Body

- Printing Speed

- 500800 pcs/hour PPM

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Plate Type

- Flat Conveyor Belt

- Print Direction

- Horizontal

- Ink Type

- Compatible with Water-Based, Plastisol, and Discharge Inks

- Color Management

- Manual Control

- Working Temperature

- Up to 180 C Celsius (oC)

- Power

- 6 kW Watt (w)

- Width

- 900 mm Millimeter (mm)

- Weight (kg)

- Approx. 270 kg Kilograms (kg)

- Dimension (L*W*H)

- 2600 x 900 x 1250 mm Millimeter (mm)

- Exhaust System

- Integrated for Efficient Ventilation

- Safety Features

- Overheating Protection, Emergency Stop Switch

- Voltage

- 220V/380V, 50 Hz

- Temperature Adjustment

- Variable Control

- Conveyor Speed

- Adjustable via Controller

- Heating Element Type

- Infrared (IR) Tubes

- Maintenance

- Easy Access Panels

Textile Curing Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 4 Units Per Month

- Delivery Time

- 3-4 Week

- Packaging Details

- As per customer requirement

About Textile Curing Machine

Textile Curing Machine

CureTex is specially designed for drying jobs printed with wide range of inks on textiles. Built for long life and maximum performance, CureTex is M/s.Umrao Automation Pvt. Ltd.s premium ceramic dryer for screen printing dryer. It's available in belt widths from 16" to 60".

Not only does it have the highest production capacity in its class of conveyor dryers, it's also the most energy efficient as in this radiation heat transfer technology used which having 90-95% efficiency instead of less efficient convection heat transfer technology. Heavy duty thermal 50 MM thick with single side silver foil Rock - wool insulation prevents heat from migrating into workplace. Entry and exit openings can be quickly and easily raised and lowered with convenient height adjustment.

Fast cure rates and high product throughput maximize conveyor dryer capacity and minimize per- unit cost Suspended ceramic heater mounting panel is used which prevents from heat dissipaon to adjacent machine parts & metal cabinet.

Proportional Integral Differential (PID) control allows the dryer to power up gradually to avoid maximum amperage loads during initial warm-up. Thyrister power regulator with PID controller helps maintain even temperatures during production by controlling electric row rather than using the full-load/no-load approach.

PID control ensures consistency by keeping dryer, chamber heat within 1o Celsius of target temperature at thermocouple.

The control panel allows easy monitoring and adjustment of temperature, and belt speed settings. Reliable, heavy-duty, variable-frequency AC-drive geared motor powers CureTex's heat resistant on-coated per glass conveyor belt with crowned roller system. Crowned rollers ensures accurate belt alignment and counters etc of deselection.

Automatic shutdown sequence keeps the blower and belt running until the conveyor dryer chamber has cooled.

Air cooled cabinet ensures long life for electrical components Easy & at low cost spare part available. The dryer is completely portable in design for ease of mobility or it can be anchored to the door with its own foundation bolts for a more permanent location.

Efficient Infrared Technology for Curing

Harnessing infrared (IR) tubes, this curing machine delivers uniform heat distribution, optimizing drying and curing performance even with different ink types. You can set and adjust the working temperature easily, ensuring precise results and avoiding ink migration.

Customizable Controls and Safety Assured

Equipped with digital temperature and speed controllers, operators have full manual control over color management and curing intensity. Enhanced safety features, including overheating protection and an emergency stop switch, provide peace of mind and compliance with workplace safety standards.

Optimized for High-Volume Textile Production

Designed with a sturdy mild steel body and a wide 900 mm conveyor belt, this machine is tailored for continuous operations. The integrated exhaust system ensures efficient ventilation, while maintenance is straightforward due to easily accessible panels, keeping your production running smoothly.

FAQs of Textile Curing Machine:

Q: How does the infrared (IR) tube heating system enhance the curing process in this machine?

A: The IR tube heating system provides consistent and controlled heat distribution, rapidly drying and curing textiles printed with various inks. This technology allows for precise temperature adjustments, reducing energy consumption and improving curing quality.Q: What types of inks are compatible with this textile curing machine?

A: This machine is suitable for curing prints made with water-based, plastisol, and discharge inks, making it versatile for a wide range of textile applications and production needs.Q: When should the temperature and conveyor speed be adjusted during operation?

A: Adjustments to temperature and conveyor speed should be made based on the ink type, fabric thickness, and desired curing time to optimize results and prevent under or over-curing.Q: Where can this curing machine be installed and utilized effectively?

A: It is ideal for factories, printing units, textile processing facilities, and export houses requiring high-volume and continuous textile curing. The compact design and robust construction suit professional production environments.Q: What maintenance procedures are recommended to ensure optimal performance?

A: Routine maintenance includes checking heating elements, cleaning the exhaust system, inspecting safety features, and utilizing the easy-access panels for regular internal checks and servicing, ensuring machine longevity and consistent output.Q: How do the integrated safety features benefit operators during usage?

A: Overheating protection monitors temperature, preventing dangerous surges, while the emergency stop switch instantly shuts down the machine if needed. These features significantly minimize risks and enhance workplace safety.Q: What is the main benefit of using this machine for textile curing applications?

A: The main benefit is its ability to cure large volumes of printed textiles efficiently and reliably, allowing manufacturers to meet production demands while achieving high-quality, durable print finishes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Printing Press Machine Category

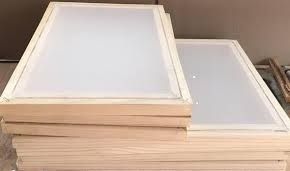

Wooden Screen Printing Frame With Mesh

Price 2000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Manual

Computerized : No

Size : Standard/Customizable

Ink Type : Other, All Purpose/Water Based

Roll To Roll Printing Machine

Price 2200000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : Yes

Size : 20" x 30"

Ink Type : UV Curing Ink

Roll to Roll Automatic Screen Printing Machine

Price 1960000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : Yes

Size : 08

Ink Type : Other

Roll To Roll 3 Colour With UV Screen Printing Machine

Price 4060000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : Yes

Size : 15" x 20"

Ink Type : Other

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free