UV Curing Dryer 25

Price 500000 INR/ Piece

UV Curing Dryer 25 Specification

- Type

- UV Curing Dryer

- Material

- Mild Steel

- Printing Speed

- 45 meter/mitutes m/m

- Computerized

- Yes

- Automatic Grade

- Automatic

- Print Direction

- Uni-Directional

- Ink Type

- UV Curing Ink

- Color Management

- Other

- Control System

- PLC Control

- Power

- 300 To 600 Watts Watt (w)

- Warranty

- One Year

UV Curing Dryer 25 Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- Days

- Main Domestic Market

- Bihar, Himachal Pradesh, Delhi, West Bengal, Haryana, Punjab, Arunachal Pradesh, Dadra and Nagar Haveli, Madhya Pradesh, Jharkhand, Chhattisgarh, Uttarakhand, Kerala, Assam, Lakshadweep, Tamil Nadu, Meghalaya, Pondicherry, Manipur, Central India, Andaman and Nicobar Islands, South India, All India, Tripura, Goa, East India, Chandigarh, Uttar Pradesh, Maharashtra, Odisha, Rajasthan, Andhra Pradesh, North India, Nagaland, Sikkim, Karnataka, Gujarat, Daman and Diu, Jammu and Kashmir, Telangana, West India, Mizoram

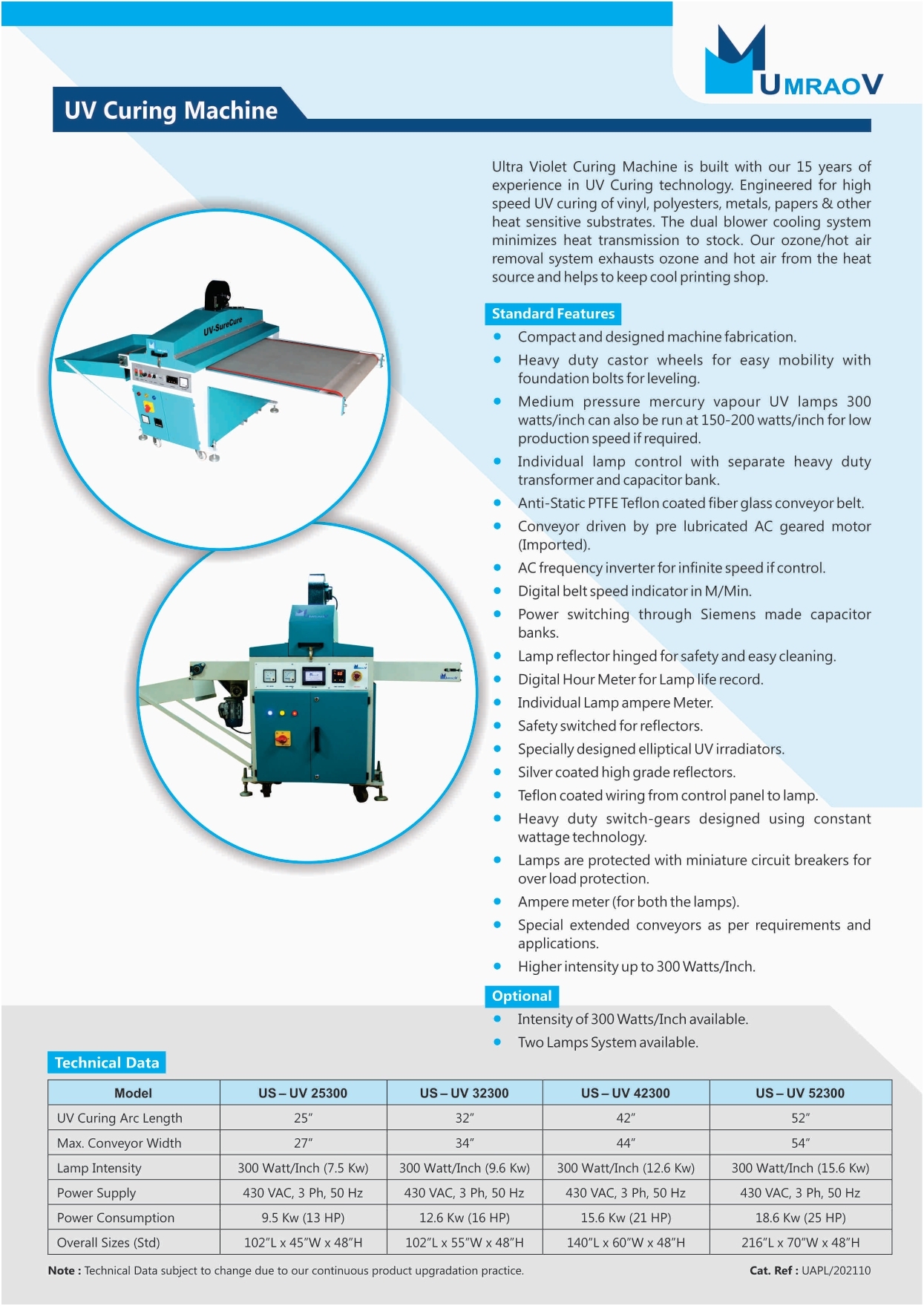

About UV Curing Dryer 25

Specifications

| Minimum Order Quantity | 1 Piece |

| Model/Type | UV 25 300W |

| Usage/Application | Curing |

| Production Mode | Semi Automatic |

| Material | Mild Steel |

| Printing Technology | Post Press |

| Ink Type | UV |

| Capacity | 45 meter/mitutes |

| Brand/Make | Umrao Automation Pvt. Ltd. |

| Features | Compact and designed machine fabrication |

| Power Supply | 430 VAC,3Ph,50 Hz |

| Brand | Umrao Automation Pvt. Ltd. |

| Uv Lamp Power | 300 To 600 Watts |

| Automation Grade | Automatic |

| Design | Customized |

| Frequency | 50-60 Hz |

| Voltage | 430 VAC |

| Country of Origin | Made in India |

| Current | 30 A |

| Humidity | 40-60% HR |

Advanced PLC Control System

The UV Curing Dryer 25 is equipped with a robust PLC (Programmable Logic Controller) system, allowing seamless automation and customization of curing processes. This advanced control delivers consistent performance, enhanced safety features, and ease of operation, making it an asset for busy manufacturing lines. It ensures high precision and adaptability, reducing human error and optimizing workflow for superior curing results.

Superior Material Construction

Built from high-quality mild steel, this UV curing dryer promises durability and lasting performance. The sturdy construction offers resistance to industrial wear and tear, making it suitable for continuous use in demanding environments. This ensures long-term reliability and reduces maintenance frequency, providing outstanding value for exporters, manufacturers, and suppliers seeking dependable drying solutions.

FAQs of UV Curing Dryer 25:

Q: How does the UV Curing Dryer 25 operate?

A: The UV Curing Dryer 25 operates using a computerized PLC control system that automates the drying process. Users can easily set parameters and monitor operations for optimal UV ink curing, ensuring precision and efficiency in each batch.Q: What are the benefits of using a PLC-controlled UV curing system?

A: A PLC-controlled UV curing system like the UV Curing Dryer 25 offers enhanced automation, consistent performance, and improved safety. It minimizes manual intervention, improves accuracy, and streamlines the curing process for better quality output.Q: When is the UV Curing Dryer 25 typically used in the printing process?

A: This device is employed immediately after ink application to ensure rapid and thorough curing of UV inks. Its quick curing process at speeds of up to 45 meters per minute supports high-volume production and quick turnaround times.Q: Where can the UV Curing Dryer 25 be installed?

A: The dryer is suitable for integration into various industrial printing setups and can be installed in manufacturing units, print shops, or any facility handling large-scale UV ink printing. Its robust design allows for adaptability in diverse working environments.Q: What types of inks work best with this UV curing dryer?

A: The machine is specifically designed for UV curing inks, delivering outstanding curing efficiency and compatibility. It ensures optimal drying and bonding of UV-based inks on a variety of substrates, enhancing print durability.Q: What is the warranty coverage for the UV Curing Dryer 25?

A: The product comes with a comprehensive one-year warranty, covering manufacturing defects and major component failures to ensure customer peace of mind and uninterrupted operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Curing Machines Category

CureTex Textile Dryer 25

Price 450000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : High Grade Steel Construction

Power : 430 VAC Volt (v)

Computerized : No

Type : CureTex Textile Dryer 25

IR Flash Cure Machine

Price 210000.0 INR / Unit

Minimum Order Quantity : 1 Piece

Material : Steel

Power : 380 V Volt (v)

Computerized : No

Type : IR Flash Cure Machine

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free