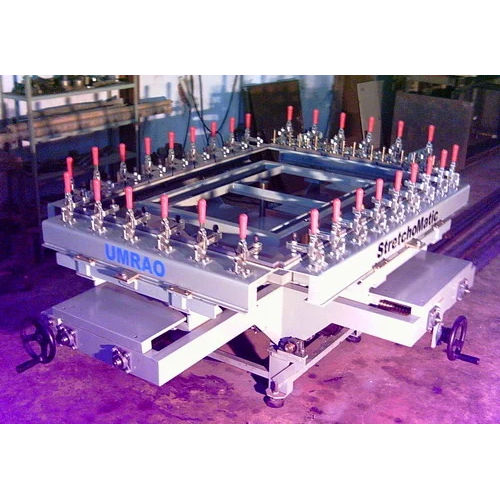

Economical Fabric Stretching Machines

Price 365000 INR/ Unit

Economical Fabric Stretching Machines Specification

- Type

- Fabric Stretching Machines

- Material

- Mild Steel

- Capacity

- 1000 meters/day

- Computerized

- No

- Automatic Grade

- Manual

- Plate Type

- Flat Plate

- Print Direction

- Bidirectional

- Color Management

- Manual

- Control System

- Manual Lever

- Working Temperature

- 10C - 35C

- Power

- 3 kw Watt (w)

- Size

- 1.5 m x 3 m

- Width

- 1.5 m

- Weight (kg)

- 250 kg

- Dimension (L*W*H)

- 3000 x 1500 x 1350 mm

- Noise Level

- < 75 dB

- Made in

- India

- Mounting Type

- Floor Mounted

- Voltage

- 220 V AC, Single Phase

- Operation

- Foot pedal supported

- Frame Holding

- Adjustable clamps for various frame sizes

- Tension Adjustment

- Manual screw tensioner

- Safety Features

- Overload protection, Emergency Stop

- Application

- Textile Screen Printing Preparation

- Surface Finish

- Powder Coated

Economical Fabric Stretching Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cheque

- Supply Ability

- 3 Units Per Month

- Delivery Time

- Days

- Packaging Details

- As per customer requirement

- Main Domestic Market

- All India, East India, Sikkim, Uttar Pradesh, Kerala, Uttarakhand, Delhi, West India, Andaman and Nicobar Islands, Telangana, Lakshadweep, Tripura, Gujarat, South India, Goa, Maharashtra, Chhattisgarh, Rajasthan, Himachal Pradesh, Dadra and Nagar Haveli, Mizoram, West Bengal, Central India, Andhra Pradesh, Tamil Nadu, Manipur, Chandigarh, Madhya Pradesh, Arunachal Pradesh, Daman and Diu, Pondicherry, Assam, Jharkhand, Odisha, Nagaland, Karnataka, North India, Jammu and Kashmir, Haryana, Bihar, Meghalaya, Punjab

About Economical Fabric Stretching Machines

Specifications

| Minimum Order Quantity | 1 Piece |

| Model Name/Number | ST M 6484 |

| Machine Type | Manual |

| Voltage | 380 V |

| Country of Origin | Made in India |

| Power | 3 kw |

| Stretching Platform | 1.5 m x 3 m |

| Application | Advertising Printing |

Versatile Frame Handling

Equipped with adjustable clamps, the machine easily adapts to various frame sizes, making it an ideal solution for diverse textile screen printing needs. Its versatility ensures that different projects can be tackled without the need for frequent adjustments or additional equipment.

User-Friendly Operation and Safety

Designed with convenience in mind, the fabric stretching machine utilizes a foot pedal for straightforward activation. Enhanced safety comes from integrated overload protection and an emergency stop button, creating a secure working environment for operators while minimizing the risk of equipment damage.

Robust Performance and Construction

Engineered from mild steel and finished with durable powder coating, this machine is built to withstand industrial usage. Its floor-mounted design, manageable weight of 250 kg, and compact footprint (3000 x 1500 x 1350 mm) make it practical for various production spaces, supporting reliable output of up to 1000 meters per day.

FAQs of Economical Fabric Stretching Machines:

Q: How does the manual screw tensioner work for fabric stretching in this machine?

A: The manual screw tensioner allows operators to adjust the fabrics tension by turning screws, ensuring consistent and even stretching across the frame. This manual control provides fine-tuned adjustment, crucial for achieving optimal printing results.Q: What safety features are included with the Economical Fabric Stretching Machine?

A: This machine is equipped with overload protection to prevent damage from excessive force and an emergency stop button for immediate shutdown in case of an emergency, prioritizing operator safety and equipment longevity.Q: When is foot pedal operation particularly beneficial in fabric stretching?

A: Foot pedal operation is advantageous during hands-on tasks, enabling users to control the machine while keeping both hands free to position materials precisely. This enhances efficiency and accuracy, especially in high-throughput production environments.Q: Where can this stretching machine be installed and what are its mounting requirements?

A: Designed for floor mounting, the machine has a stable base and compact dimensions (3000 x 1500 x 1350 mm). It fits well in most textile production areas and requires a single-phase 220 V AC power connection with proper floor space for safe operation.Q: What is the process for adjusting frame sizes in this fabric stretching machine?

A: The adjustable clamps on the machine are designed to securely hold frames of various sizes. Operators simply reposition or adjust the clamp settings to fit the required frame, accommodating a range of standard and custom screen sizes used in textile printing.Q: What are the operational benefits of using this specific fabric stretching machine?

A: Users benefit from reliable tension adjustment, low noise levels (<75 dB), robust build quality, and easy manual controls. The machine is energy-efficient (3 kW power) and capable of high daily capacities (up to 1000 meters), making it suitable for manufacturers aiming to boost productivity.Q: Who manufactures and supplies this fabric stretching machine?

A: This machine is manufactured, exported, and supplied by reputable firms based in India, specializing in textile machinery production. The unit is made from mild steel and finished for durability, ensuring consistent quality and performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screen Printing Machines Category

Print Area 20"x30" Screen Printing Machine

Price 615000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 230V AC Volt (v)

Size : Customized

Automatic Grade : SemiAutomatic

Type : Screen Printing Machine

Roll to Roll Printing Machine with IR

Price 1950000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 15 kw22 kw Watt (w)

Size : 15

Automatic Grade : Automatic

Type : Roll to Roll Printing Machine

Screen Printing Machine (15)

Price 450000 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 230 VAC Volt (v)

Size : Standard

Automatic Grade : SemiAutomatic

Type : Screen Printing Machine

Wedding Card Printing Machine

Price 350000.0 INR / Unit

Minimum Order Quantity : 1 Piece

Power : 380 Volt (v)

Size : 10" x 15"

Automatic Grade : SemiAutomatic

Type : Wedding Card Printing Machine

Send Inquiry

Send Inquiry