Screen Printing Machine (15)

Price 450000 INR/ Piece

Screen Printing Machine (15) Specification

- Type

- Screen Printing Machine

- Material

- Mild Steel

- Capacity

- 1500 Impressions/hour

- Printing Speed

- Up to 1500 sheets/hour

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Plate Type

- Flat Bed

- Print Direction

- Uni-Directional

- Ink Type

- Solvent Based Ink

- Color Management

- Manual

- Control System

- Digital Control Panel

- Working Temperature

- 5C - 45C

- Power

- 230 VAC Volt (v)

- Size

- Standard

- Width

- 1200 mm

- Weight (kg)

- 300 Kilograms (kg)

- Dimension (L*W*H)

- 1800 mm 1200 mm 1300 mm

Screen Printing Machine (15) Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 7-10 Days

- Main Domestic Market

- All India

About Screen Printing Machine (15)

Specifications

| Minimum Order Quantity | 1 Piece |

| Object To Be Printed | Wedding Card |

| Usage/Application | Printing |

| Model Name/Number | VP1520 |

| Voltage | 230 VAC |

| Capacity | 900-1000 Impression/hour |

| Finish | Color Coated |

| Brand | Umrao Automation Pvt. Ltd. |

| Automation Grade | Semi-Automatic |

| Weight | Approx 300 Kg |

| Power Consumption | 2 HP / 2.3 Kw |

| I Deal In | New Only |

| Country of Origin | Made in India |

Precision Printing for Diverse Applications

Delivering exceptional registration accuracy of 0.02 mm, the Screen Printing Machine (15) ensures precise, consistent prints on materials including paper, glass, plastics, PVC, and metal. Its adjustable squeegee speed and uni-directional print flow are ideally suited for quality-demanding projects in industries such as packaging and commercial signage.

Designed for Performance and Durability

Constructed from mild steel, the machine offers long-term durability and stable operation under industrial workloads. The servo motor-drive system supports semi-automatic performance, while a digital control panel facilitates easy adjustment and monitoring of print parameters. Its large print and frame sizes accommodate a wide range of requirements.

Efficient Output with Flexible Operation

With a capacity of up to 1500 impressions per hour and a standard working temperature range (5C45C), this machine suits demanding production schedules. Manual color management and solvent-based inks provide versatility and allow fine-tuning for every job. Compatibility with optional dryers enhances productivity further.

FAQs of Screen Printing Machine (15):

Q: How is the print registration maintained at such high accuracy on this screen printing machine?

A: The Screen Printing Machine (15) employs a servo motor-driven mechanism and advanced registration controls to achieve a registration accuracy of 0.02 mm. This ensures consistent alignment and sharp printing, especially important for multi-layer or intricate designs.Q: What substrates and applications is this machine suitable for?

A: This model prints effectively on a variety of substrates, including paper, plastics, PVC, glass, and metal. It is well-suited for industrial and commercial uses such as packaging, signage, and product labeling, offering versatility for various production needs.Q: When should an air supply be connected to the machine?

A: An air supply of 6 bar is only necessary if a dryer is attached to the system. For standard operation without a dryer, the machine functions using its standard electrical supply (230 VAC) and does not require compressed air.Q: Where can this machine be installed for optimal performance?

A: For optimal performance, the Screen Printing Machine (15) should be installed in an environment with stable temperatures ranging from 5C to 45C. Adequate space is needed to accommodate its dimensions (1800 mm 1200 mm 1300 mm) and provide clearance for substrate handling and maintenance.Q: What is the process for adjusting the printing speed and squeegee pressure?

A: Adjustments to printing speed and squeegee pressure are made via the digital control panel. This system allows operators to fine-tune settings, ensuring optimal ink deposition and print quality across various materials and job types.Q: How does manual color management work on this machine?

A: Manual color management requires the operator to manually mix and load solvent-based inks, allowing greater flexibility for custom color requirements. The operator controls how and when inks are applied, which is advantageous for small batch runs or unique color demands.Q: What are the key benefits of choosing this semi-automatic screen printing machine?

A: Key benefits include high output rates (up to 1500 impressions/hour), exceptional registration precision, versatility across multiple substrates, durable construction, and user-friendly digital controls. It is a reliable choice for businesses needing consistent, high-quality flat-bed screen printing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screen Printing Machines Category

Screen Printing Machinery

Price 350000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Size : Standard

Power : 380 V Volt (v)

Type : Screen Printing Machinery

Roll to Roll Printing Machine with IR

Price 1950000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Size : 15

Power : 15 kw22 kw Watt (w)

Type : Roll to Roll Printing Machine

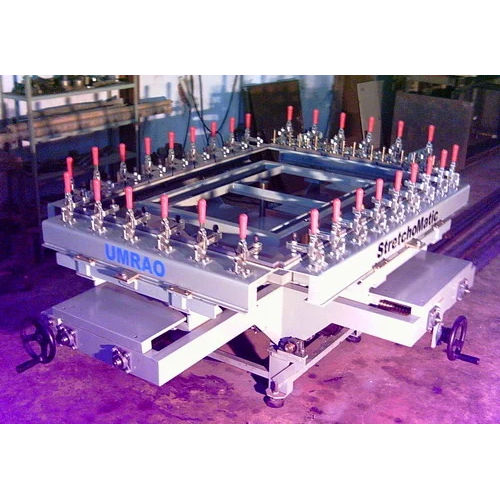

Economical Fabric Stretching Machines

Price 365000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Manual

Size : 1.5 m x 3 m

Power : 3 kw Watt (w)

Type : Fabric Stretching Machines

Metal Halide Lamp Exposing Machine 32

Price 240000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Size : 800X1000 mm

Power : 250 W Watt (w)

Type : Halide Lamp Exposing Machine

Send Inquiry

Send Inquiry