Large UV Curing Dryer 42

Price 650000 INR/ Unit

Large UV Curing Dryer 42 Specification

- Power

- 300Watt/Inch Watt (w)

- Fuel Type

- Electric

- Power Consumption

- Depends on length and usage

- Heat Source

- UV Lamp

- Usage

- Industrial

- Material

- Industrial Metal Body

- Voltage

- 220-240V AC

- Temperature

- 200 Celsius (oC)

- Product Type

- Large UV Curing Dryer 42

- Technology

- Ultraviolet (UV) Curing

- Dimension (L*W*H)

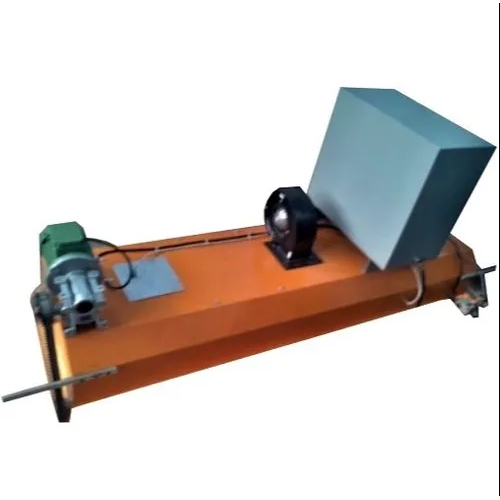

- Approx. 2400mm x 1200mm x 1400mm

- Color

- Structure Orange

- Safety Features

- Overheat and overcurrent protection

- Cooling System

- Air cooled with exhaust

- Operating Frequency

- 50/60 Hz

- Conveyor Speed

- 0.5-6 m/min adjustable

- Lamp Quantity

- 2-4 UV Lamps

- Curing Area

- 1050mm x required length

- Installation Type

- Floor Mounted

- Control Panel

- Digital/Analog

- Max Workpiece Width

- 1050mm

Large UV Curing Dryer 42 Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 7-10 Days

- Main Domestic Market

- All India

About Large UV Curing Dryer 42

Specifications

| Minimum Order Quantity | 1 Piece |

| Automation Grade | Automatic |

| Max Temperature | 200 |

| Model/Type | UV 42300 |

| Color | Structure Orange |

| Uv Lamp Power | 300Watt/Inch |

| Brand | Umrao Automation Pvt Ltd |

| Automatic Grade | Automatic |

| Design | Customized |

Advanced UV Curing Technology

Harnessing ultraviolet light, the Large UV Curing Dryer 42 accelerates the curing process of coatings, adhesives, and inks on various materials. Its 2-4 high-intensity UV lamps deliver rapid, uniform curing, optimizing industrial production lines and enhancing product output quality.

Customizable Curing and Operation

Adapt to distinct production needs with adjustable conveyor speeds, customizable curing area length, and selectable digital or analog control systems. Whether working with different substrates or production volumes, flexibility is built into every aspect of this floor-mounted UV curing dryer.

Safety and Efficiency at Its Core

Equipped with overheat and overcurrent protection, alongside an advanced air-cooled system, the UV Curing Dryer 42 offers dependable, energy-efficient operation. Its robust industrial metal body ensures durability, while carefully engineered exhaust mechanisms support consistent temperature management up to 200C.

FAQs of Large UV Curing Dryer 42:

Q: How does the Large UV Curing Dryer 42 improve the curing process in industrial applications?

A: The dryer utilizes high-powered UV lamps and adjustable conveyor speeds to deliver rapid, uniform curing of coatings and inks. This process results in faster production lines and higher-quality finishes compared to traditional heat-based drying methods.Q: What workpiece sizes and materials can this UV curing machine accommodate?

A: The machine supports workpieces up to 1050mm in width and an adjustable curing area length. Its robust design and adjustable settings make it compatible with a wide range of industrial materials requiring UV-curable coatings.Q: When should I consider using the UV Curing Dryer 42 in my manufacturing process?

A: If you require accelerated curing times, enhanced surface quality, or the ability to process larger workpieces efficiently, integrating the UV Curing Dryer 42 can significantly benefit your production workflow.Q: Where is the ideal installation location for this curing dryer?

A: As a floor-mounted unit, the Large UV Curing Dryer 42 should be installed in a well-ventilated industrial workspace with access to 220-240V AC power and sufficient room for its dimensions (approx. 2400mm x 1200mm x 1400mm).Q: What safety features are built into the Large UV Curing Dryer 42?

A: The dryer incorporates overheat and overcurrent protection to safeguard equipment and operators. An efficient air-cooling system with exhaust ensures safe temperature management during prolonged use.Q: How do I control and monitor the curing process?

A: Operators can choose between digital and analog control panels to precisely adjust conveyor speed, monitor lamp status, and oversee curing parameters for optimal results.Q: What are the primary benefits of using this UV Curing Dryer?

A: Key advantages include efficient power consumption tailored to workload, fast curing for increased output, high reliability, built-in safety mechanisms, and the flexibility to meet diverse industrial needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in UV Dryers Category

Ultra Violet Curing Machine

Price 635000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 380 Volt (v)

Product Type : Post Press

Color : Orange

Material : Steel

Uv Curing System

Price 1330000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 430 V Volt (v)

Product Type : Uv Curing System

Color : Blue

Material : Other

Horizontal Dryer Machine

Price 349999.0 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 380 V Volt (v)

Product Type : Horizontal Dryer Machine

Color : Orange

Material : Other

UV Curing Dryer

Price 340000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 380 Volt (v)

Product Type : UV Curing Dryer

Color : Green

Material : Other, Mild Steel

Send Inquiry

Send Inquiry