Uv Curing System

Price 1330000 INR/ Piece

Uv Curing System Specification

- Heat Source

- UV Lamps

- Fuel Type

- Electric

- Usage

- Industrial

- Material

- Other

- Voltage

- 430 V Volt (v)

- Product Type

- Uv Curing System

- Technology

- UV Curing

- Color

- Blue

- Warranty

- 1 Year

Uv Curing System Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7-10 Days

- Main Domestic Market

- All India

About Uv Curing System

Specifications

| Minimum Order Quantity | 1 Piece |

| Material | Mild Steel |

| Power Source | Electrical |

| Usage/Application | Printing |

| Country of Origin | Made in India |

| Automation Grade | Automatic |

| Voltage | 430 V |

| Design | Standard |

| Ink Type | UV |

| Brand | Umrao Automation Pvt. Ltd. |

| Power | 3 Ph |

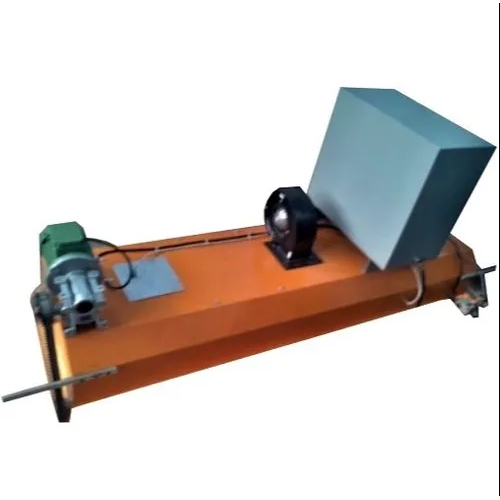

Advanced UV Curing Technology

Utilizing twin mercury vapor lamps, this UV curing system ensures rapid and consistent curing for a variety of industrial processes. Its optimized airflow and digital controls provide precise management, making it ideal for high-quality output in demanding settings.

Efficient and Flexible Operation

The adjustable conveyor speed supports both fast-paced production and delicate curing requirements, allowing versatility across multiple applications. Air-cooling technology keeps the unit at optimal temperatures, minimizing downtime and ensuring safety.

Reliable and Easy-to-Use Design

With a user-friendly digital control panel and robust floor-mounted installation, the system is straightforward to operate and maintain. Its blue exterior provides a modern look while protecting critical components inside.

FAQs of Uv Curing System:

Q: How does the air-cooled UV curing system maintain lamp efficiency during continuous use?

A: The air cooling method effectively dissipates heat from the UV lamps, ensuring the system operates within optimal temperature ranges. This prolongs lamp life and maintains consistent curing efficiency, even during extended production runs.Q: What are the primary applications of this floor-mounted UV curing system?

A: This system is designed for industrial-level coating, printing, and adhesive curing. Its precise UV exposure ensures rapid hardening and high-quality finishes, suitable for various materials across manufacturing sectors.Q: When should the conveyor speed be adjusted on this UV curing machine?

A: Adjust the conveyor speed based on the specific curing requirements of your material and application. A slower speed is ideal for thicker coatings or higher adhesive loads, while faster speeds are suitable for thin or less demanding materials.Q: Where can the UV curing system be installed for optimal results?

A: The unit is intended for floor-mounted installation in industrial environments with adequate airflow and electrical supply. Ensure the area is free from excessive dust and direct moisture for optimal performance and longevity.Q: What is the process for operating the UV curing system safely?

A: Operation includes powering on the system, setting the desired conveyor speed via the digital control panel, and loading materials onto the belt. Appropriate safety gear, such as UV-blocking protective equipment, should be worn at all times during operation.Q: How does using this UV curing system benefit industrial production?

A: Employing UV technology allows for faster curing times, increased throughput, and enhanced product quality. The automation and adjustable settings also improve consistency and reduce labor, boosting overall productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in UV Dryers Category

Large UV Curing Dryer 42

Price 650000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Structure Orange

Product Type : Large UV Curing Dryer 42

Material : Other, Industrial Metal Body

Voltage : 220240V AC

Ultra Violet Curing Machine

Price 635000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Orange

Product Type : Post Press

Material : Steel

Voltage : 380 Volt (v)

Horizontal Dryer Machine

Price 450000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Orange

Product Type : Horizontal Dryer Machine

Material : Other, Mild Steel / Stainless Steel

Voltage : 380 V Volt (v)

UV Curing Dryer

Price 340000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Green

Product Type : UV Curing Dryer

Material : Other, Mild Steel

Voltage : 380 Volt (v)

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free