Mini Verti Print Screen Printing Machine

Price 350000 INR/ Unit

Mini Verti Print Screen Printing Machine Specification

- Type

- Screen Printing Machine

- Computerized

- Yes

- Automatic Grade

- Semi-Automatic

- Ink Type

- Other

- Size

- 10

- Width

- 10 Inch (in)

- Warranty

- One Year

Mini Verti Print Screen Printing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- Unit

- Delivery Time

- Week

- Packaging Details

- As per customer requirement

- Main Domestic Market

- Manipur, Chandigarh, Himachal Pradesh, Tripura, Andaman and Nicobar Islands, Pondicherry, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Delhi, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, West Bengal, Haryana, Gujarat, North India, Andhra Pradesh, Kerala, Central India, Chhattisgarh, Uttar Pradesh, All India

About Mini Verti Print Screen Printing Machine

Mini Verti Print Screen Printing Machine

We are introduces the fines and most flexible range of trouble free semi automatic flatbed Screen Printing machine. The machine is easy to setup; easy to control gives maximum stability at full production speed with top quality prints and with accuracy required for high quality screen printing. Squeegee head on hardened steel shafts with linear bearing motion to give accurate and vibration free squeegee movement. Pnenumatic measurable squeegee pressure adjustment.

Applications: Flat surface printing on ceramic Tiles Transfers, printed Circuit Board, Transfers, Paper, Stickers, Metal Labels, Membrane swtich Printing, Commercial screen printing etc.

Standard Features

- Adjustable squeegee & food speed via Linear Rod less Cylinder (pre-lubricated) coupled with AC frequency inverter.

- Infinite variable and independent print and flood speeds adjustable from 0 to max speed.

- Squeegee carriage on Hard Chrome Plated solid steel shaft with linear bearing motion (IKO Japan)

- Pnenumatically adjustable squeegee & flood pressure, fine pressure adjustments with dial indicators.

- Adjustable squeegee angle from 0 to 30o

- Aluminum extruded squeegee holder & coater for even pressure

- Bed movement for registration X, Y, & Rotary(+-)10mm

- Selectable Print Cycle Flood First & then Print First & then Flood.

- Emergency Rod/Stop for safety of operator.

- Castor wheels for easy mobility.

- Printing operation by food switch or automatic cycle with dwell time 0 to 10 sec.

Efficient and Compact Printing Solution

The Mini Verti Print Screen Printing Machine combines advanced computerized control with semi-automatic functionality to deliver high-quality prints in a compact form. Its 10-inch width is perfect for small-scale operations, and the robust design ensures durability for frequent use. Suitable for various industries, it simplifies the printing process and boosts productivity.

Quality Assurance and Support

Each machine comes with a one-year warranty, backed by expert support from Indian exporters, manufacturers, and suppliers. This guarantees optimal performance and peace of mind for users, making operations smoother and more reliable for printing businesses.

FAQs of Mini Verti Print Screen Printing Machine:

Q: How does the Mini Verti Print Screen Printing Machine operate?

A: The machine operates with computerized controls, allowing users to automate specific printing tasks while maintaining hands-on oversight via its semi-automatic mechanism. This streamlines setup, alignment, and ink application for accurate and consistent prints.Q: What are the benefits of using this screen printing machine?

A: Benefits include enhanced efficiency, precise print quality, reduced manual labor, and suitability for limited spaces. Its computerized and semi-automatic features help improve workflow and reduce production errors.Q: When is it ideal to use this machine for printing?

A: This machine is ideal for small to medium batch production, especially when consistent output and space-saving features are important priorities. It is suitable for frequent printing needs, prototyping, or short-run jobs.Q: Where can I purchase this machine in India?

A: The Mini Verti Print Screen Printing Machine is available through authorized exporters, manufacturers, and suppliers across India. You can contact these providers or visit their official websites for purchasing and support.Q: What is the process for maintaining the machine?

A: Regular maintenance involves cleaning the screen, checking alignment, monitoring software updates, and ensuring proper lubrication of moving parts. Periodic inspections help maintain performance and reduce downtime.Q: How do I utilize the computerized functions on this machine?

A: Users can program print cycles, control the speed and pressure settings, and manage workflow through its integrated computer interface. The software guides operators for seamless adjustments and repeatable results.Q: What usage scenarios is this printing machine best suited for?

A: It is best suited for textile printing, graphic production, promotional material creation, and small-scale manufacturing where high accuracy and automation are required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Printing Press Machine Category

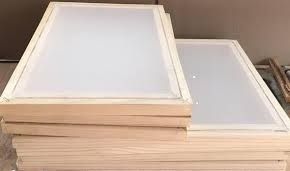

Wooden Screen Printing Frame With Mesh

Price 2000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Printing Speed : 9001000 Impression/hour

Automatic Grade : Manual

Width : Varies as per requirement

Roll To Roll 3 Colour With UV Screen Printing Machine

Price 4060000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Printing Speed : 1800 Impressions/hr mm/m

Automatic Grade : Automatic

Width : 15 Inch (in)

Balloon Screen Printing Machine

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Printing Speed : 18002000 Pcs/Hour mm/m

Automatic Grade : SemiAutomatic

Width : 150 Millimeter (mm)

Automatic Screen Printing Machine

Price 625000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Printing Speed : 550 Impression/Hour m2/hr

Automatic Grade : SemiAutomatic

Width : 12 Inch (in)

Send Inquiry

Send Inquiry