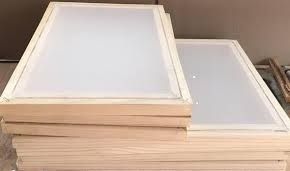

Wooden Screen Printing Frame With Mesh

Price 2000 INR/ Unit

Wooden Screen Printing Frame With Mesh Specification

- Type

- Mesh Screen Frame

- Material

- Wood & Mesh

- Capacity

- 900-1000 Impression/hour T/hr

- Printing Speed

- 900-1000 Impression/hour

- Computerized

- No

- Automatic Grade

- Manual

- Plate Type

- Flat

- Print Direction

- Unidirectional

- Ink Type

- All Purpose/Water Based

- Color Management

- Manual

- Working Temperature

- Room Temperature

- Size

- Standard/Customizable

- Width

- Varies as per requirement

- Weight (kg)

- 1.5 - 3 kg (depending on size)

- Dimension (L*W*H)

- Typically 20 x 24 x 1.25 or customized

- Mesh Material

- Polyester/Nylon

- Mesh Count

- Available in 80-180 TPI (threads per inch)

- Frame Finish

- Smooth, Sanded Edges

- Eco Friendly

- Yes

- Edge Protection

- Tape Sealed/Covered Edges

- Frame Joint

- Mortise and Tenon/Staple Reinforced

- Frame Shape

- Rectangular

- Application

- Textile, T-Shirt, Paper, Glass, Wood Printing

- Reusability

- Yes, Washable and Re-coatable

Wooden Screen Printing Frame With Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 1-2 Days

- Packaging Details

- As per customers requirement

- Main Domestic Market

- Himachal Pradesh, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Delhi, South India, North India, East India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Chandigarh, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Mizoram, Meghalaya, Manipur, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Pondicherry, Maharashtra, Gujarat, Andhra Pradesh, Kerala, Central India, Odisha, All India

About Wooden Screen Printing Frame With Mesh

We are offering here the Wooden Screen Printing Frame With Mesh that is suitable for manual printing. However, this kind of wood frame material is solvent-resistant, has poor water resistance, easily deformed after immersion, and affects printing accuracy. This kind of Wood Screen Printing Screen Frames is commonly used in the past and is rarely used now. The design to be printed is then created as a stencil onto this mesh, with the areas not to be printed being blocked out, and the areas to be printed left as mesh. The Wooden Screen Printing Frame With Mesh is very effective and useful.

Durable Construction and Versatile Application

Each wooden frame is engineered with mortise and tenon or staple enhanced joints for longevity, making them ideal for consistent use in textile, garment, paper, glass, and wood printing. Their edge protection ensures mesh integrity, while eco-friendly materials promote sustainable practices.

Customizable Mesh and Frame Options

Select from polyester or nylon mesh in a range of 80180 TPI, tailored to your printing needs. Standard dimensions are 20 x 24 x 1.25 inches, but custom sizes can be ordered to suit specific project requirements. The weight varies from 1.5 to 3 kg based on size.

Reusable and Easy to Maintain

Designed for reliable reusability, these frames withstand multiple print cycles and are easily washable and re-coatable. Tape-sealed edges guard against wear, making them long-lasting tools for manual, unidirectional print applications. Suitable for room temperature working environments and simple manual color management.

FAQs of Wooden Screen Printing Frame With Mesh:

Q: How do I select the correct mesh count for my printing application?

A: Choose a mesh count between 80 and 180 TPI based on your printing medium and desired print detail. Lower counts are suitable for heavier inks and textiles, while higher counts are ideal for fine detail on paper, glass, or wood.Q: What is the process for cleaning and re-coating the screen frame after use?

A: Simply wash the mesh with water or a cleaning solution to remove ink after printing. The frame is designed to be re-coated and reused, ensuring long-term utility with proper maintenance.Q: Where can I use the Wooden Screen Printing Frame With Mesh?

A: These frames are suited for screen printing on textiles, t-shirts, paper, glass, and wood, making them versatile for both commercial and artisanal printing environments.Q: What are the benefits of tape-sealed and covered edges?

A: Tape-sealed and covered edges protect the mesh from fraying and ink seepage, extending the lifespan of the frame and ensuring cleaner print results.Q: When should I recoat the mesh on my screen frame?

A: Recoat the mesh whenever you notice a loss of print quality or after several uses to maintain sharp, consistent prints. Regular maintenance supports optimal performance and longevity.Q: Is the Wooden Screen Printing Frame eco-friendly and safe to use?

A: Yes, the frame is manufactured from sustainable wood materials and reusable mesh, making it eco-friendly. All components are safe for manual operation at room temperature.Q: What printing speed or capacity should I expect?

A: You can achieve a printing speed of approximately 9001000 impressions per hour, depending on the frame size and printing setup, which is ideal for small to medium-scale production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Printing Press Machine Category

Four Pillar Screen Printing Machine

Price 1650000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One Year

Size : 48

Computerized : Yes

Automatic Grade : SemiAutomatic

Roll To Roll Printing Machine

Price 2200000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One Year

Size : 20" x 30"

Computerized : Yes

Automatic Grade : Automatic

Roll To Roll 3 Colour With UV Screen Printing Machine

Price 4060000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One Year

Size : 15" x 20"

Computerized : Yes

Automatic Grade : Automatic

4-Pillar Screen Printing Machine

Price 780000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One Year

Size : FP2436

Computerized : Yes

Automatic Grade : SemiAutomatic

Send Inquiry

Send Inquiry